What Is a Magnetic Bar? An In-Depth Guide to Industrial Magnetic Filtration

In industrial settings, the quality and safety of production processes rely heavily on precise filtration systems. One of the most critical components in modern magnetic separation is the magnetic bar, sometimes referred to as a magnet rod or tube magnet. But what is a magnetic bar, how does it work, and why is it indispensable in today’s industrial applications?

In this post, we’ll explore the structure, applications, and technical details behind magnetic bars. We’ll also highlight how Magfine Canada’s magnetic bars stand out as a reliable and customizable solution for industries across Canada and beyond.

Understanding the Magnetic Bar

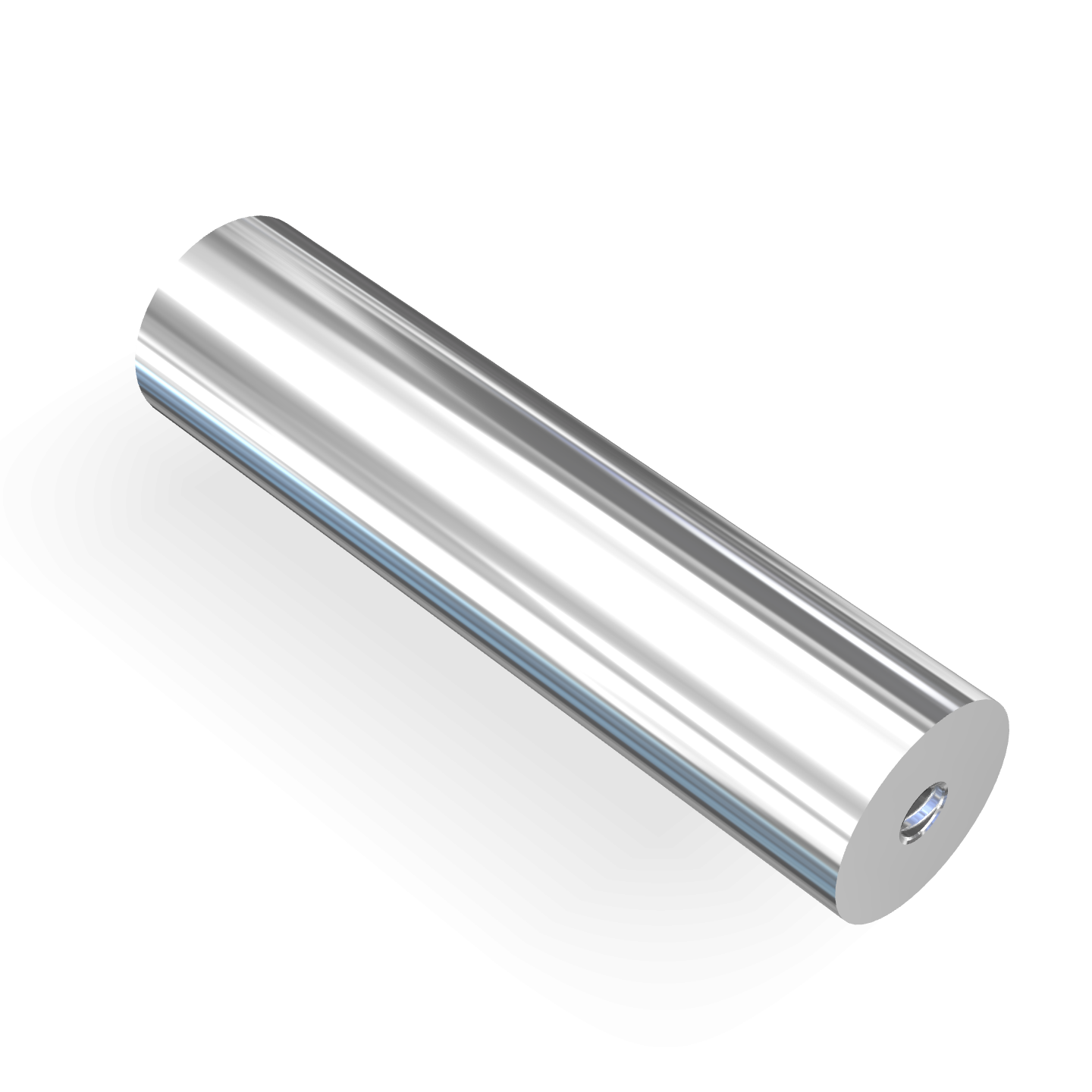

A magnetic bar is an enclosed tube containing strong magnets—usually neodymium magnets—that generate a powerful magnetic field. These bars are designed to attract and retain ferrous particles from dry or wet product streams, acting as a filtration system in food, pharmaceutical, chemical, plastics, and recycling industries.

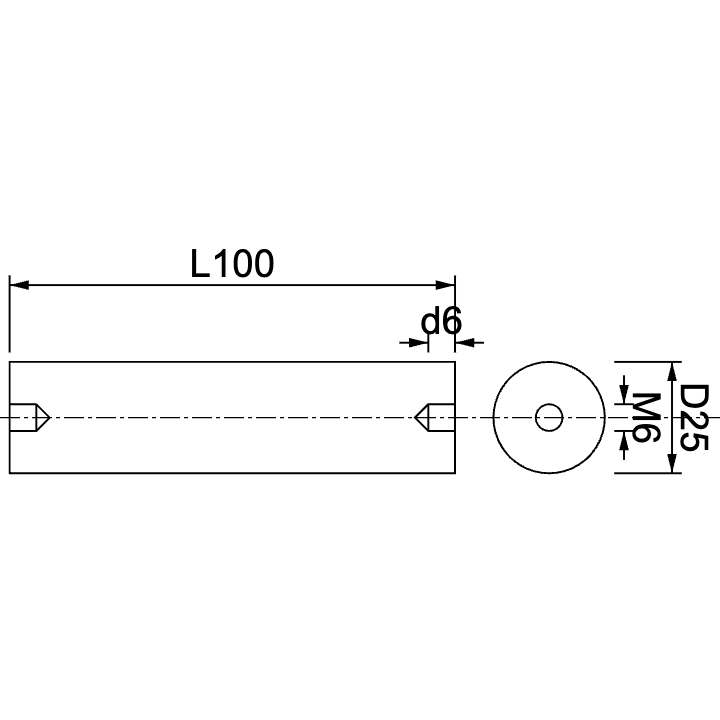

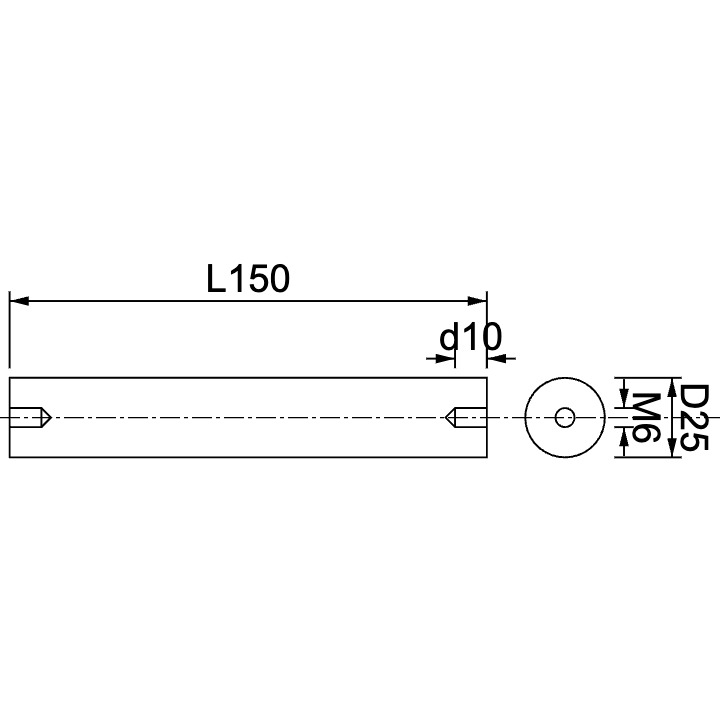

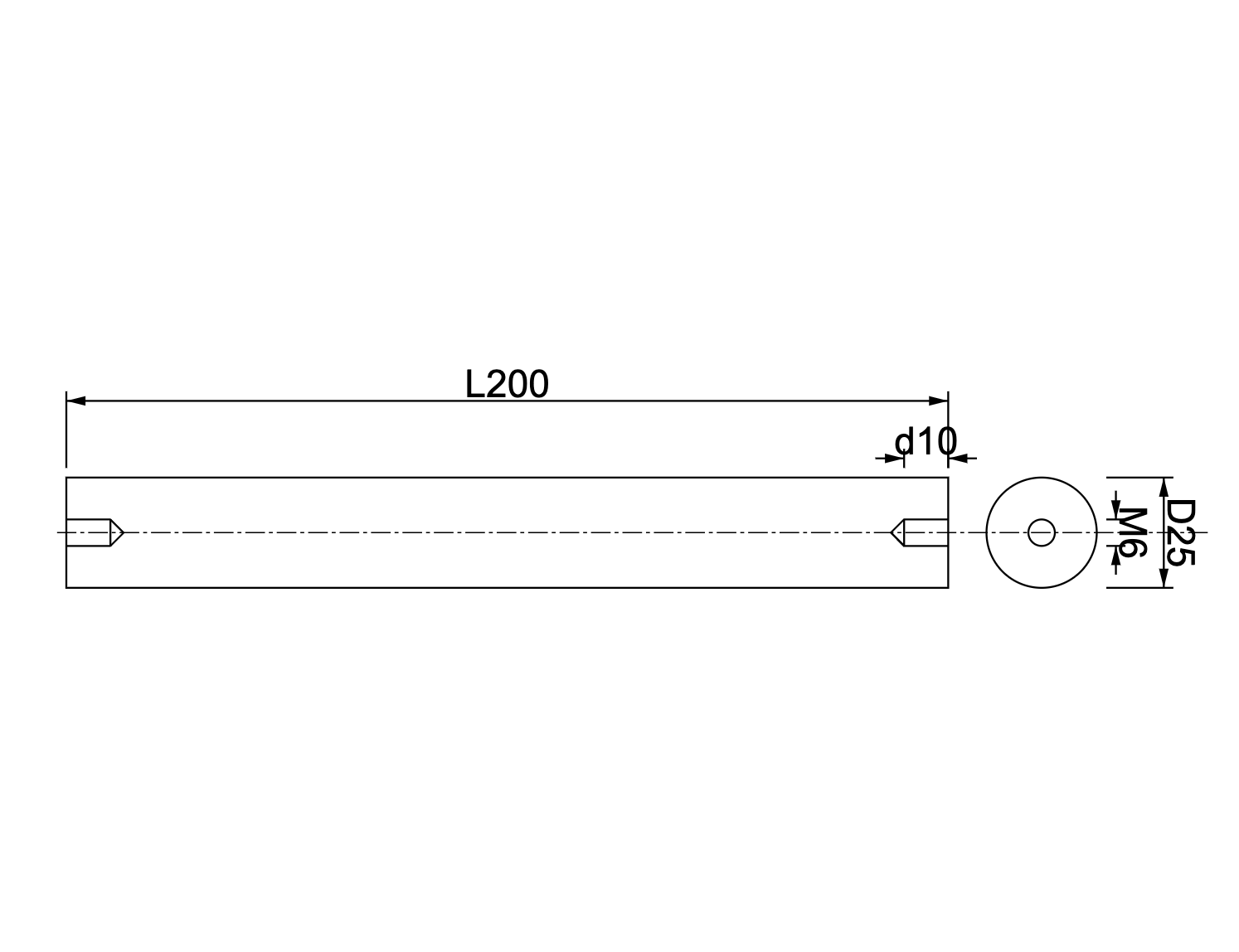

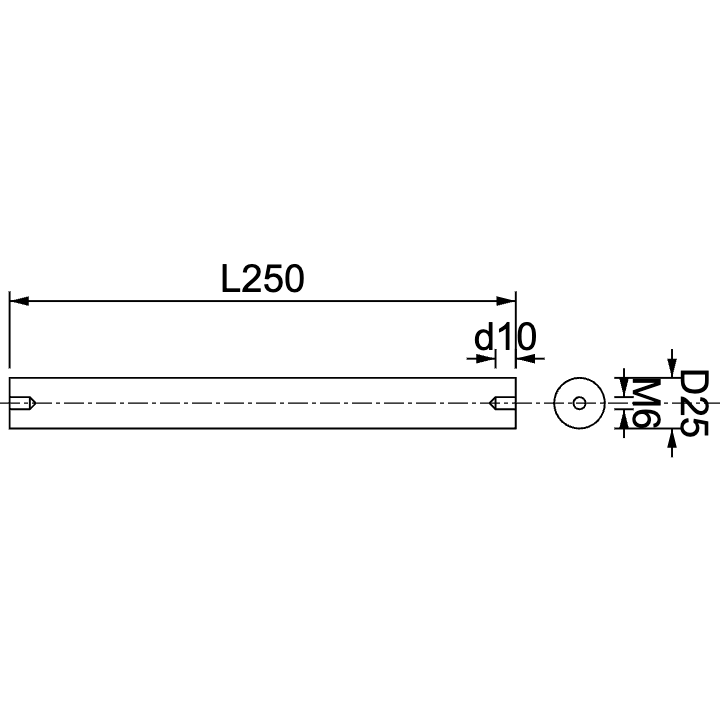

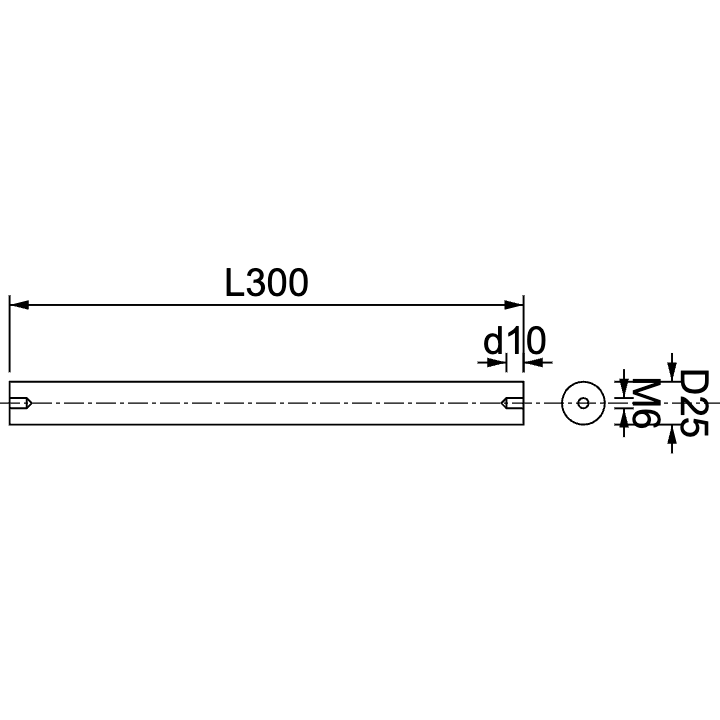

At Magfine, our magnetic bars are available in various shapes and sizes, including round, square, and triangular profiles. Each shape is designed to optimize sediment collection and maximize magnetic surface area for efficient particle capture.

How Do Magnetic Bars Work?

Inside the stainless steel housing of the magnetic bar, multiple neodymium magnets are arranged such that similar poles repel each other. This internal configuration generates a dense, uniform magnetic field that attracts even the finest ferrous particles within a radius of approximately 40 mm.

The bars typically exhibit a magnetic flux density of 1000 to 1400 mT, making them powerful enough to operate effectively in challenging environments. Whether you're separating contaminants in bulk powders or preventing metallic damage in processing equipment, magnetic bars deliver unmatched reliability.

Key Features of Magfine’s Magnetic Bars

- Powerful internal industrial magnets arranged for maximum flux

- Corrosion-resistant stainless steel housing

- Multiple sizes and custom options available

- RoHS and REACH compliant materials

- Easy installation and maintenance

All Magfine magnetic bars are manufactured with strict quality control, ensuring consistent performance and durability in Canadian industrial settings.

Applications Across Industries

Magnetic bars are used across various sectors, including:

- Food Processing: Prevent contamination in flour, spices, and dairy powder production.

- Pharmaceuticals: Ensure product purity and regulatory compliance.

- Plastics: Remove metal particles that could damage injection molding equipment.

- Recycling: Enhance material recovery by separating ferrous contaminants.

Looking for high-quality magnets in Canada? Magfine offers a wide range of industrial magnets tailored to Canadian businesses, including custom magnet solutions for complex separation challenges.

Customization Options

At Magfine, we understand that no two operations are the same. That’s why we offer:

- Custom diameters and lengths

- Threaded ends (M8, M10, M12, etc.) for easy mounting

- Special shapes (triangular, square)

- Varying magnet strengths based on the material flow

Our team works closely with clients to ensure that every magnetic bar is designed for optimal integration into their processing system. You can contact our team for specific customization requests.

How to Maintain a Magnetic Bar

Proper maintenance extends the lifespan and efficiency of your magnetic bars. Follow these simple guidelines:

- Regularly wipe the surface clean with a soft cloth.

- Avoid using sharp tools to remove attached particles.

- Inspect for signs of wear or corrosion periodically.

- Store in a dry place to prevent oxidation.

With proper care, Magfine’s neodymium magnetic bars can serve your operations for many years with consistent performance.

Why Choose Magfine?

As a trusted supplier of industrial magnets and neodymium magnets in Canada, Magfine is committed to delivering excellence. Our magnetic bars are manufactured to exceed industry standards while remaining competitively priced. Whether you need a small batch for R&D or a high-volume custom order, we’re here to support your production goals.

Q&A: Everything You Need to Know About Magnetic Bars

What materials are magnetic bars made from?

Magnetic bars are typically made using stainless steel casings and powerful internal neodymium magnets for long-lasting, corrosion-resistant performance.

How strong are Magfine’s magnetic bars?

Our bars deliver a flux density of around 1000–1400 mT and a capture range of approximately 40 mm.

Can I order custom sizes?

Absolutely. We offer fully customizable lengths, diameters, thread ends, and magnet grades. Reach out to us with your requirements.

Where are your magnetic bars made?

We manufacture and ship our magnets directly from Canada, ensuring fast delivery and consistent quality across North America.

Are your magnets certified?

Yes, all our products are RoHS and REACH compliant, and tested to meet industrial safety standards.

Final Thoughts

Whether you're upgrading your existing magnetic filtration system or installing one from scratch, Magfine Canada offers premium-quality magnetic bars built for real-world applications. Explore our full line of magnetic separation products today to find the right solution for your operation.

If you're looking for neodymium magnets or industrial magnets in Canada, trust Magfine for quality, service, and results.