Understanding Metal Yoke Parts with Countersink and Raised Features – Precision Components for Magnetic Assembly

When it comes to building powerful magnetic assemblies, the right support hardware is just as critical as the magnets themselves. At Magfine.ca, we specialize in not only offering high-performance neodymium magnets and industrial magnets, but also providing essential accessories such as metal yoke parts with countersink and raised features.

Whether you're designing a custom magnetic circuit, fabricating high-strength magnet assemblies, or upgrading your prototyping toolkit, these small but mighty components can have a significant impact. In this post, we’ll dive deep into what metal yokes are, why countersink and raised options matter, and how these parts can enhance the performance of your magnets in Canada and beyond.

What Are Metal Yoke Parts?

Metal yoke parts, also known as magnet holders or back plates, are supporting components that serve to improve magnetic field distribution and secure magnets in mechanical applications. They’re especially common in configurations where force distribution, magnetic circuit shaping, or mechanical reinforcement is needed. Yokes are frequently used in sensor systems, motor assemblies, magnetic tool holders, and speaker construction.

These parts often come in different structural configurations—like countersink and raised types—each suited to specific mounting and performance requirements.

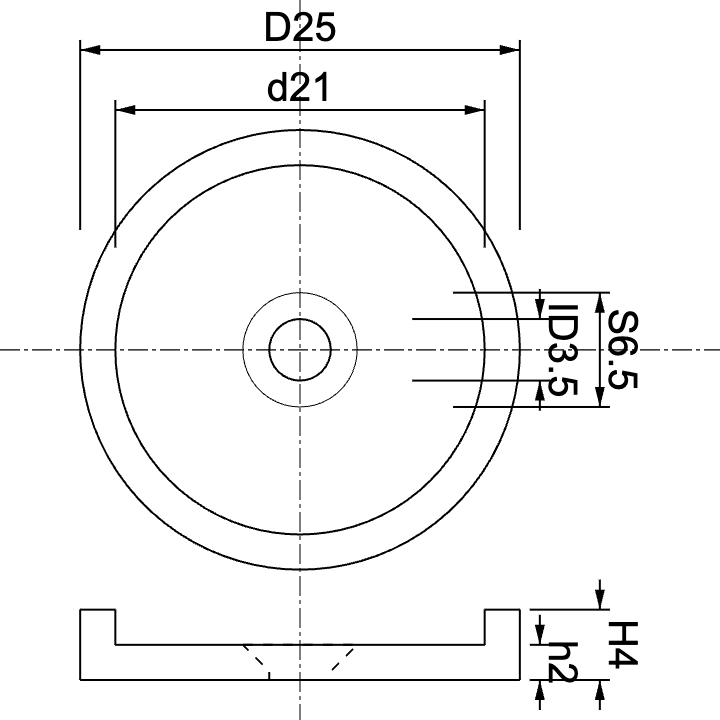

Countersink Metal Yokes

A countersink yoke has a tapered hole, allowing you to mount the yoke flush against a surface with a flathead screw. This provides:

- A clean, low-profile installation

- Increased safety in sensitive environments

- Improved mechanical integrity with flush fits

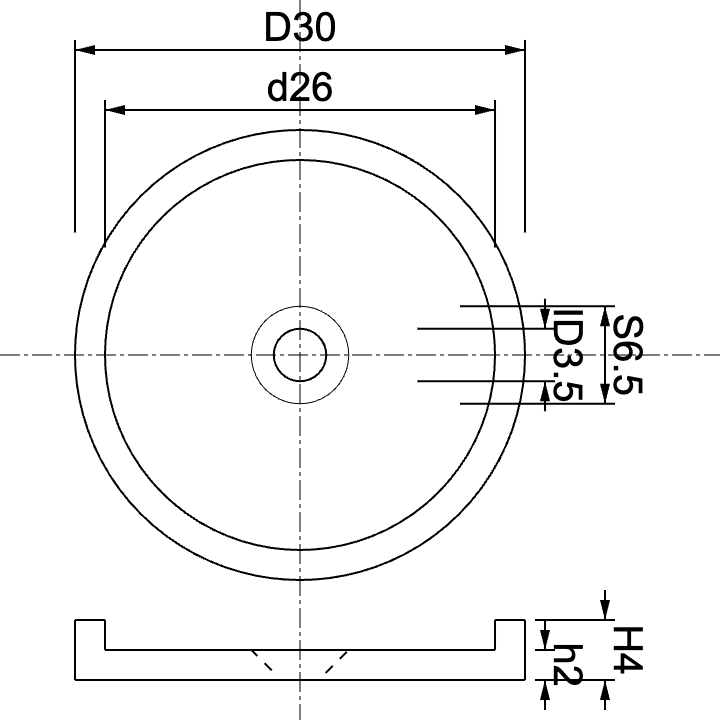

Raised Metal Yokes

Raised metal yokes feature a protruding central platform, designed to interface with magnets for enhanced magnetic contact. Benefits include:

- Increased contact surface for better magnetic flux transfer

- Improved alignment in assembly environments

- Reduced wear and tear on magnet faces

Why Pair Metal Yokes with Neodymium Magnets?

Neodymium magnets are the strongest rare-earth magnets available, but their performance can be significantly improved with the right assembly hardware. Using yokes helps optimize the magnetic circuit by directing flux more efficiently through a defined path, especially in demanding industrial applications.

For example, in a linear actuator or holding assembly, the use of a yoke improves holding force and reduces stray magnetic fields, improving overall safety and efficiency.

Applications of Metal Yoke Parts

Magfine’s metal yoke components are ideal for a range of magnetic assemblies:

- Magnetic Holding Fixtures – Secure magnets to metallic surfaces using minimal mechanical hardware.

- Sensor Assemblies – Stabilize and position magnets accurately in measurement equipment.

- Automotive Systems – Optimize magnetic field geometry in electronic controls or locking mechanisms.

- Electronics Manufacturing – Use precise yokes to control EMI shielding and magnetic interaction.

Explore Magfine’s full line of magnetic holders to see more assembly-ready solutions tailored to Canadian industry professionals.

Made for Industrial Use

Whether you're an engineer, product developer, or procurement specialist, Magfine’s yoke accessories are built to perform. Manufactured with high-tolerance machining and rust-resistant coating, these parts are compatible with our entire selection of neodymium magnets in Canada.

Each metal yoke is designed with repeatability in mind—making them ideal for batch production, prototyping, and specialized magnetic tooling systems.

Why Choose Magfine.ca?

As a proudly Canadian distributor of high-quality magnets and magnetic assemblies, we understand the importance of consistency and quick delivery. Our domestic warehouse ensures that you get your magnets in Canada without long international shipping delays. Plus, we offer competitive pricing and technical support tailored to industrial needs.

With a large inventory of industrial magnets, accessories, and mounting systems, Magfine.ca is your one-stop solution for any magnetic assembly project. From individual hobbyists to OEM production teams, we’re committed to making magnet purchasing easy and reliable.

Final Thoughts

Choosing the right hardware to complement your industrial magnet applications can mean the difference between a successful magnetic assembly and an inefficient one. Metal yoke parts with countersink and raised features offer a smart, precise solution for engineers and designers working with neodymium magnets.

At Magfine.ca, we’re dedicated to offering only the best tools and accessories to support your magnetic innovation. Explore our metal yoke collection today and give your next magnetic project the strength and stability it deserves.

Frequently Asked Questions

- What is a metal yoke used for in magnetic assemblies?

- Metal yokes serve as structural and magnetic flux-enhancing parts that hold magnets in place while improving their magnetic efficiency and safety in mechanical designs.

- What’s the difference between countersink and raised yokes?

- Countersink yokes allow flush-mounting with screws, while raised yokes provide better magnetic contact and alignment with magnets. Each has unique mechanical and magnetic advantages.

- Can I use these yokes with any type of magnet?

- They are best paired with neodymium magnets for high-performance applications, but can be compatible with other types depending on the use case.

- Where can I find magnets in Canada?

- You can purchase a wide range of magnets in Canada directly from Magfine.ca, including neodymium magnets, yoke parts, and magnetic accessories.

- Do you offer bulk pricing for industrial magnet projects?

- Yes, we provide special pricing and support for OEM, engineering, and industrial procurement projects. Contact our team directly for a custom quote.