Neodymium Cap Magnets with a Threaded Male End: A Powerhouse Solution for Secure Mounting

In the world of industrial magnets, innovation often hides in plain sight. One such unsung hero? The neodymium cap magnet with a threaded male end. These powerful, compact components serve a crucial role in a wide variety of mechanical, industrial, and even everyday applications.

But what sets them apart?

This article explores the design, advantages, and uses of threaded male end cap magnets, focusing on Magfine’s premium neodymium magnet solutions. Whether you're a procurement specialist, engineer, or a DIY enthusiast in Canada, you're about to discover why these magnets are becoming the go-to choice for secure fastening and reliable holding.

What Is a Cap Magnet with a Threaded Male End?

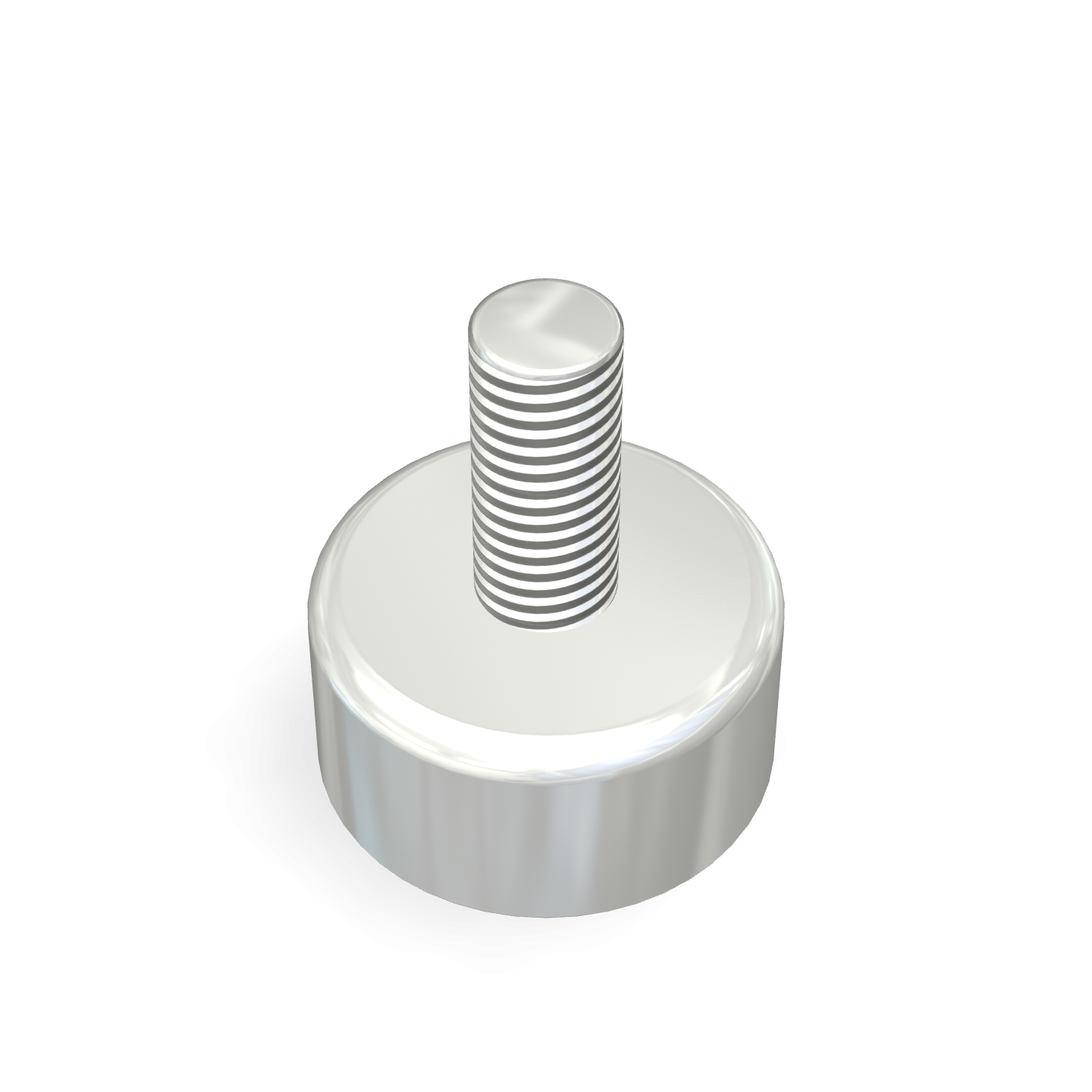

A neodymium cap magnet with a threaded male end is a specially designed magnet assembly where a strong neodymium disc is embedded inside a steel shell or pot (the "cap") and attached to a threaded stud or bolt protruding from one side. The threaded male end allows for secure mounting to various surfaces or structures, eliminating the need for adhesives or welding.

Design Advantages of Threaded Neodymium Cap Magnets

1. Enhanced Magnetic Holding Force

The steel cap redirects and focuses the neodymium magnet's magnetic field, boosting its strength by up to 20–30%. This design allows the magnet to hold significantly heavier loads compared to an unshielded disc magnet of the same size.

2. Corrosion Protection

Threaded neodymium cap magnets are often zinc or nickel plated, improving durability in industrial environments. Some models are even available with rubber coatings for use in sensitive or outdoor settings.

3. Thread Compatibility

The male thread (often M4, M5, M6, M8, or M10) makes it easy to bolt the magnet into pre-drilled panels, brackets, or machinery — no need for complicated fasteners or adhesives.

4. Reusability

Unlike adhesives, threaded connections can be removed and reused, making these magnets a sustainable solution in both prototyping and production.

Where Are Threaded Cap Magnets Used?

The versatility of threaded cap neodymium magnets means they’re seen across countless industries:

| Application | Industry |

|---|---|

| Mounting safety lights or sensors | Automotive |

| Hanging tools or fixtures in metal shops | Manufacturing |

| Positioning jigs or holders in CNC machinery | Robotics & Engineering |

| Temporary signage or display assembly | Retail & Exhibition |

| Magnetic clamping in welding setups | Construction |

| Marine or outdoor equipment assembly | Outdoor Gear |

Explore related products in our Neodymium Magnet Mounting Solutions.

Key Features of Magfine's Neodymium Threaded Cap Magnets

Magfine Corporation, headquartered in Japan with Canadian operations, designs magnet solutions that meet global industrial standards. Here’s what sets Magfine’s cap magnets apart:

- Industrial-Grade Neodymium: All magnets use high-performance N35–N52 grades.

- Precision Machining: Tight tolerances ensure perfect thread alignment.

- Custom Options: Available on request for thread pitch, length, and coatings.

- Compliance: RoHS & REACH compliant for international markets.

Technical Specifications

| Parameter | Value |

|---|---|

| Magnet Grade | N35 |

| Pull Force | 25 kg (55 lbs) |

| Outer Diameter | 25 mm |

| Height (excluding thread) | 8 mm |

| Thread Type | M5 male, 10 mm long |

| Coating | Nickel-Copper-Nickel |

| Max Operating Temperature | 80°C |

Why Canadian Businesses Trust Magfine for Magnets

Finding reliable magnets in Canada can be challenging. That’s where Magfine stands out:

- Canadian warehouse fulfillment

- Fast lead times

- Expert engineering support

- Japanese quality, North American service

Explore our Industrial Neodymium Magnet Collection.

Installation Tips for Threaded Cap Magnets

- Use Thread Lockers: Prevent loosening from vibration.

- Don’t Over-Torque: Avoid damaging the magnet or thread.

- Avoid Shear Loads: Best for direct pull applications.

- Protect Surfaces: Use rubber washers when needed.

Custom Applications? Let’s Talk.

Looking for a neodymium magnet that fits your unique needs?

Magfine offers custom threaded magnet assemblies, including:

- Stainless steel caps

- Rubber coatings

- Waterproof versions

- High-temp grades

- Extended thread lengths

Request a quote or consult with our magnet experts.

Frequently Asked Questions

What is a neodymium cap magnet with a threaded male end used for?

These magnets are designed for secure mounting and are used in industrial setups, signage, sensor positioning, and tool hanging. The threaded male end allows easy integration with brackets and panels.

Can I use these magnets outdoors?

Yes, when properly coated or sealed. Magfine offers rubber-coated and corrosion-resistant versions for outdoor or humid environments.

Are these magnets safe for electronics?

Use caution. Neodymium magnets can affect magnetic storage and sensitive components. Keep them away from hard drives or pacemakers.

Do you offer custom thread sizes?

Absolutely. Magfine provides custom solutions for thread length, size, and magnet grade. Contact us for details.

Where can I buy neodymium magnets in Canada?

You can buy industrial-grade neodymium magnets, including threaded cap types, directly from Magfine.ca with fast shipping and Canadian support.