Cap Neodymium Block Countersunk Magnets: The Hidden Power Behind Precision Assembly

When strength, accuracy, and long-term reliability are critical, there’s one magnet that quietly outperforms others in the background of countless industrial setups: the Cap Neodymium Block Countersunk Magnet. These powerful rare-earth magnets, engineered with precision and backed by superior design, are crucial in industries ranging from automotive to aerospace and from renewable energy to consumer electronics.

In this guide, we’ll dive deep into what makes these neodymium magnets so essential, how they’re used, and why Magfine Corporation is your go-to partner for sourcing industrial magnets in Canada.

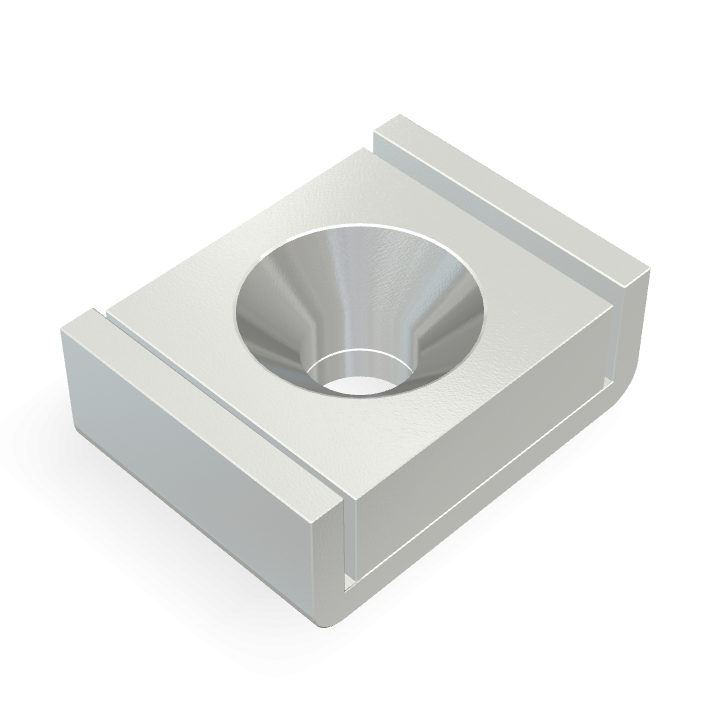

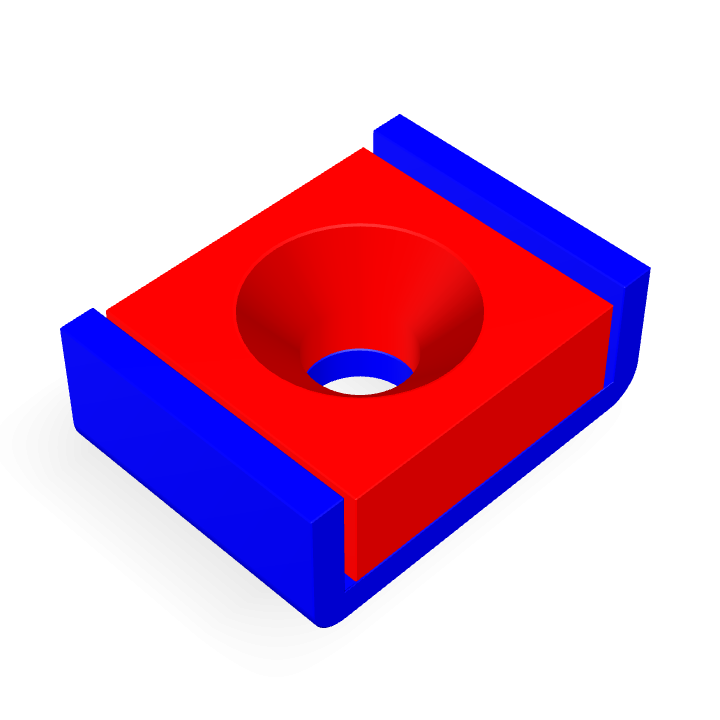

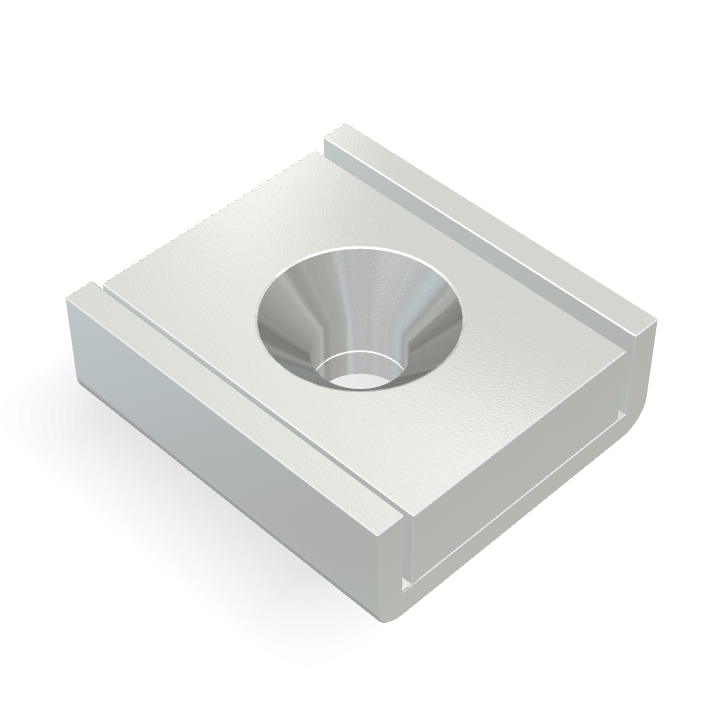

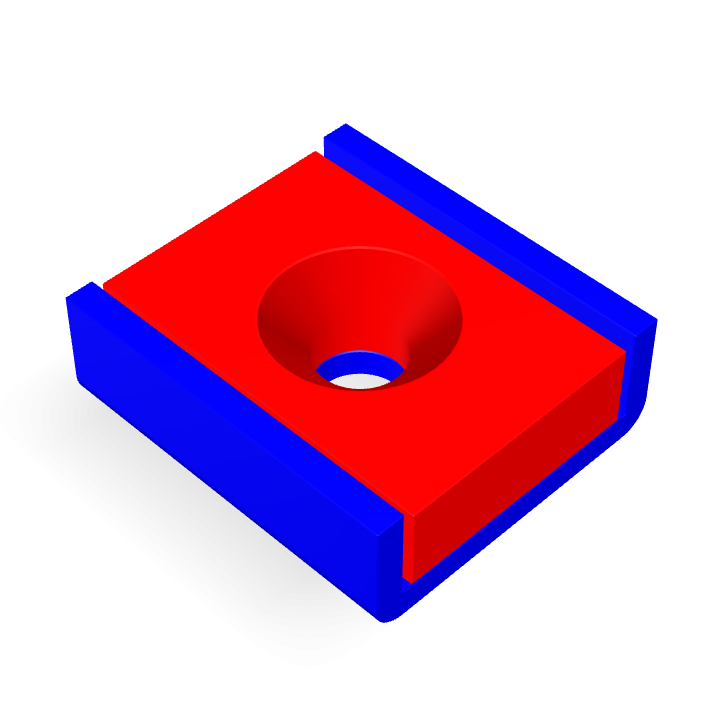

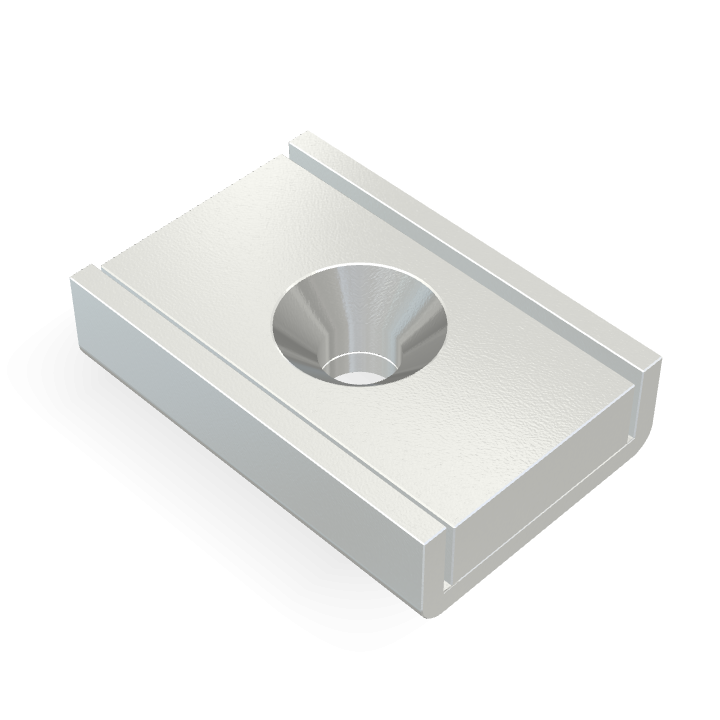

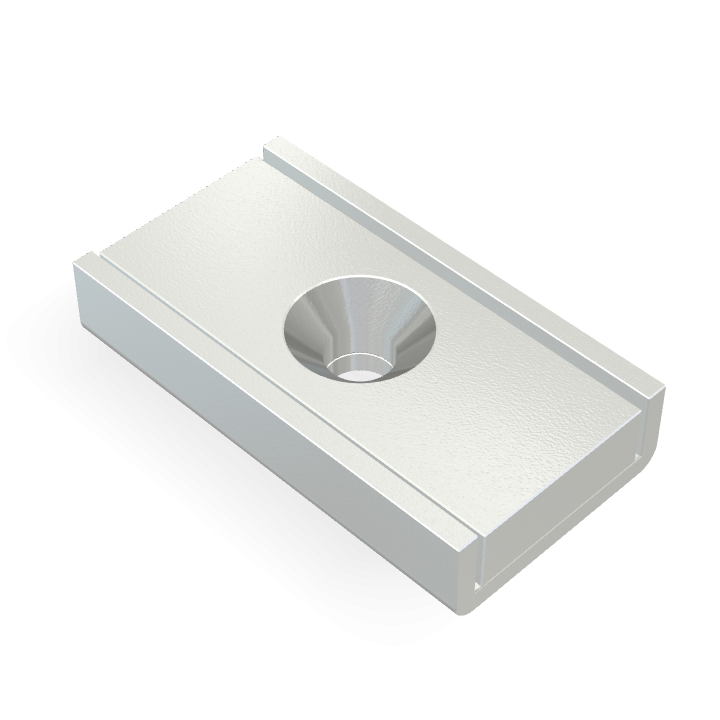

What Is a Cap Neodymium Block Countersunk Magnet?

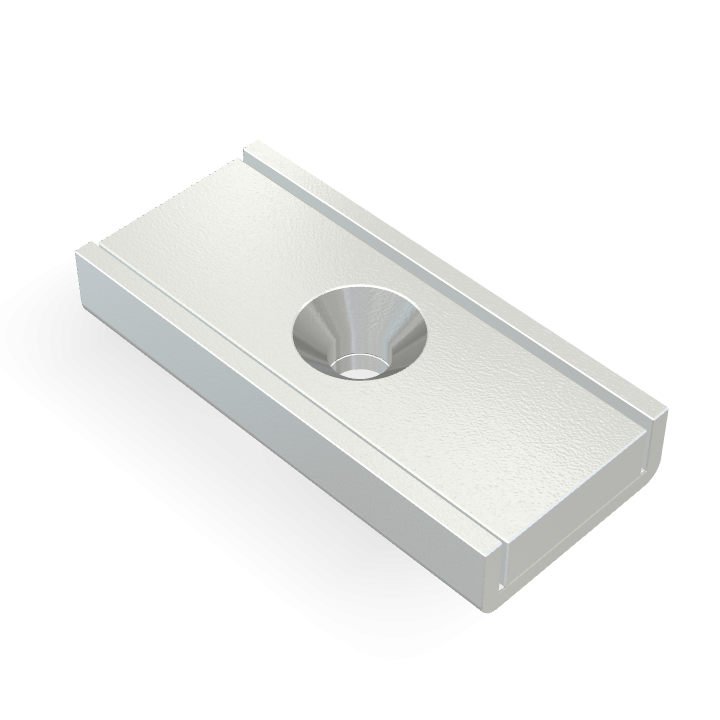

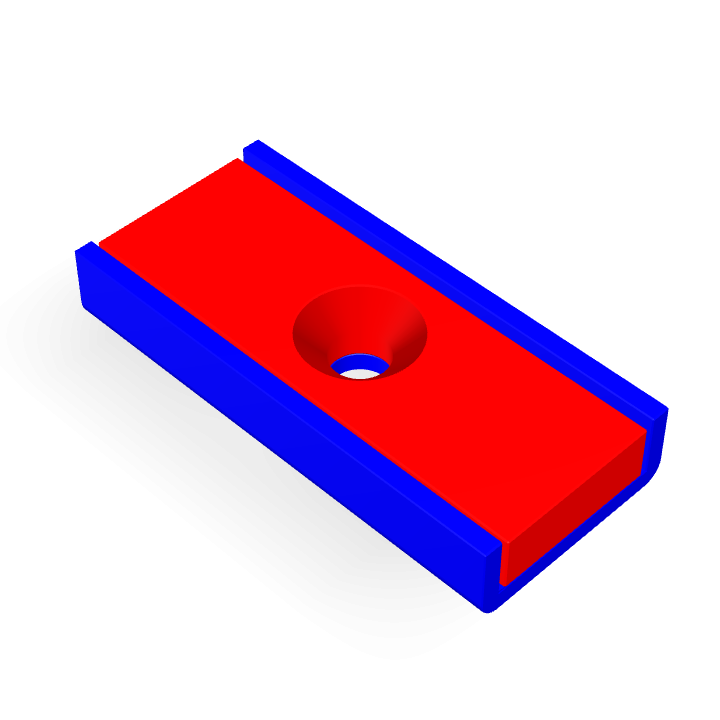

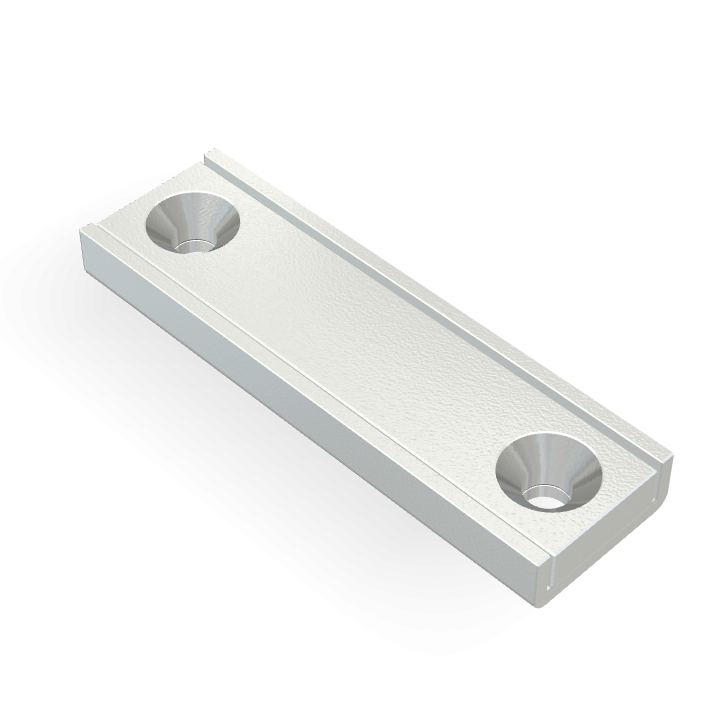

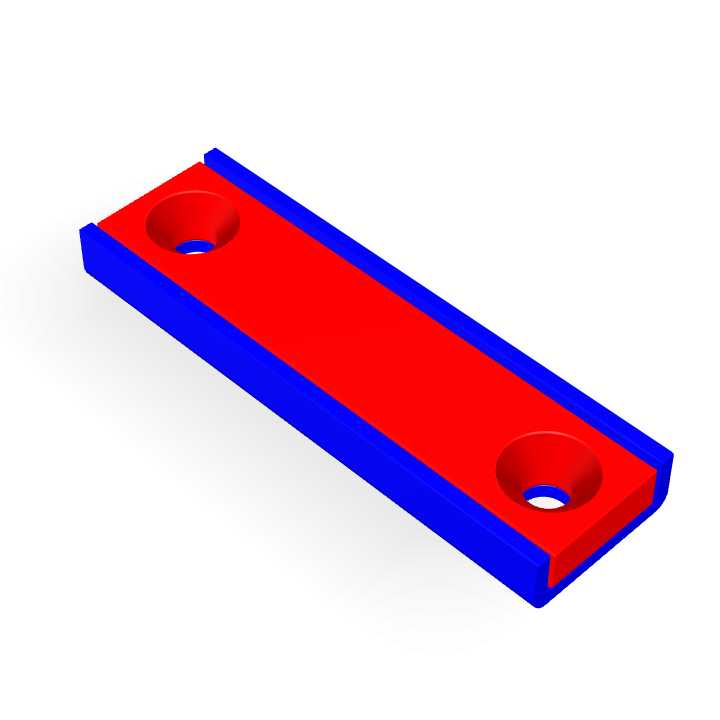

A Cap Neodymium Block Countersunk Magnet is a rectangular or square neodymium magnet designed with a recessed countersunk hole, allowing for easy mounting using a flat-head screw. Often encased in a protective steel cup or cap, this configuration enhances the magnet’s holding force while offering mechanical protection.

This makes them ideal for use in tight spaces or applications where a flush mount is necessary—think precision motors, electronic enclosures, sensor assemblies, or door latching systems in high-performance environments.

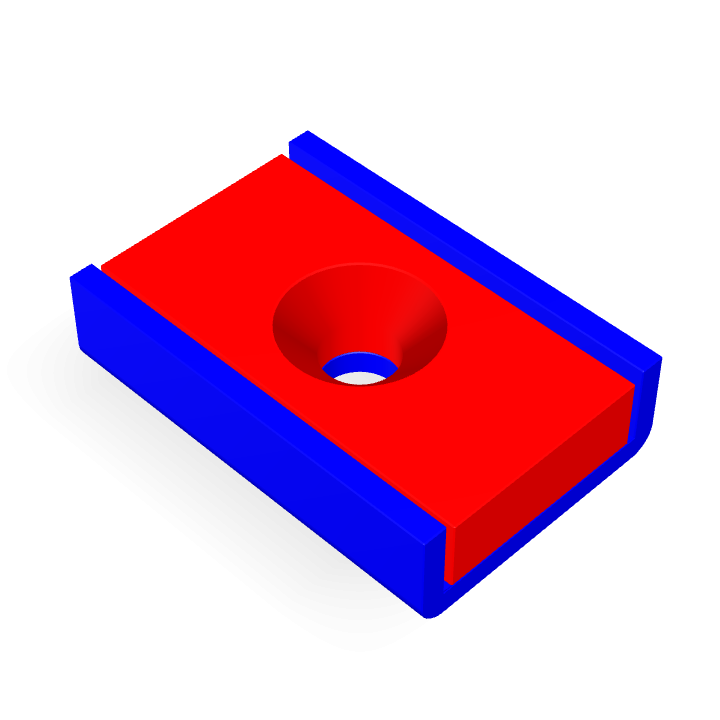

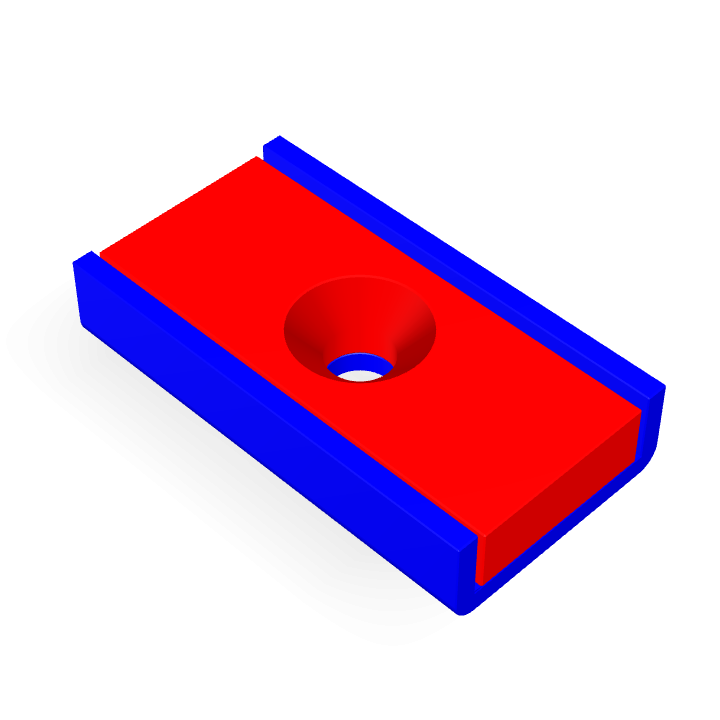

The Anatomy of a Cap Block Magnet

- Material: NdFeB (Neodymium-Iron-Boron) – the strongest rare-earth magnet material available.

- Shape: Rectangular or square block.

- Cap/Casing: Often a steel shell that redirects magnetic flux for increased surface holding power.

- Countersunk Hole: Precision-drilled to fit flat-head screws for flush mounting on various surfaces.

- Coating: Typically nickel-plated for corrosion resistance and durability.

Why Choose Cap Neodymium Block Countersunk Magnets?

Choosing the right industrial magnet is a strategic decision. Cap block countersunk magnets are a smart solution for engineers and designers who need mounting stability and high pull force in a compact form factor. Here’s why these magnets are becoming an industry standard:

1. High Strength-to-Size Ratio

Due to the neodymium core and cap design, these magnets deliver incredible strength even in small dimensions. A typical block size of 20x10x5mm can hold several kilograms under ideal conditions.

2. Enhanced Durability

The steel cap not only redirects magnetic flux but also serves as a shield, reducing wear, damage, and chipping—making them suitable for repeated mechanical use.

3. Flush Mounting for Clean Design

The countersunk hole allows screws to sit flush with the surface, making it ideal for clean and low-profile installations in design-sensitive products.

4. Corrosion Resistance

Cap magnets from Magfine’s cap neodymium block magnet collection are coated with multiple layers of nickel, copper, and nickel again—providing added resistance to rust in humid or coastal environments.

5. Repeatable, Removable Holding

These magnets are perfect for modular setups—offering strong but removable mounting that doesn’t require glue or welding.

Industrial Applications

Because of their reliable performance, cap neodymium block countersunk magnets are extensively used across sectors. Below are some real-world use cases:

- Automotive: For securely mounting panels, brackets, and sensors in tight, vibration-prone environments.

- Aerospace: Used in modular equipment mounts where weight and strength are both crucial.

- Electronics: Helps in precision placement of enclosures or parts that require easy disassembly.

- Manufacturing Fixtures: Ideal for jigs and tool holders where strength and quick access are needed.

- Retail & Displays: Perfect for shelf systems and modular signage where aesthetics and mounting simplicity matter.

Why Magfine Corporation?

Magfine Corporation brings over 35 years of technical expertise in magnetic design and rare-earth technology. With headquarters in Japan and a growing presence in North America, Magfine ensures top-tier sourcing, quality assurance, and customer service.

For Canadian industries seeking durable and high-performance magnets in Canada, Magfine’s Cap Block Countersunk Magnets are a top-tier choice. Whether you're a manufacturer, designer, or DIY enthusiast, our catalogue is tailored to meet industrial and creative needs alike.

Key advantages of buying from Magfine:

- Consistent quality backed by Japanese engineering standards

- Flexible order sizes—perfect for both large-scale and custom projects

- Quick shipping from our Canadian facility

- Expert support on magnet applications and custom solutions

Tips for Installation and Usage

To get the best results from your cap neodymium block countersunk magnets:

- Use matching countersunk screws to avoid magnetic damage.

- Install on ferromagnetic materials like steel or iron for optimal hold.

- Avoid high heat environments—neodymium loses magnetic strength at elevated temperatures.

- When placing two magnets together, align poles correctly to avoid repulsion or damage.

Explore More Magnets in Canada

Looking for other industrial-grade neodymium magnets? Check out our guides on:

Each magnet style offers different benefits. The Cap Block Countersunk design is uniquely suitable for applications where mounting, strength, and aesthetics are equally important.

Final Thoughts

Whether you’re working on a robotic assembly line, developing modular furniture, or managing an industrial process, Cap Neodymium Block Countersunk Magnets offer a smart, efficient solution. Their combination of design precision, extreme magnetic force, and mechanical reliability makes them a vital tool for anyone building high-performance systems.

For high-quality magnets in Canada, trust the experts at Magfine—where advanced magnet technology meets practical innovation.

Frequently Asked Questions (FAQ)

What is the purpose of the countersunk hole in these block magnets?

The countersunk hole allows for a flush mount using a flat-head screw. This is especially useful when space and aesthetics are a concern.

Can Cap Neodymium Block Countersunk Magnets be used outdoors?

Yes, as long as they are nickel-coated and not exposed to prolonged moisture or corrosive environments. For harsher conditions, consider epoxy-coated alternatives.

Do you offer custom sizes for industrial projects?

Absolutely. Contact us with your specifications, and we’ll be happy to assist with a custom quote and lead time.

Where are your magnets shipped from?

Orders within Canada are shipped from our local facility to ensure fast delivery and reduced cross-border delays.