How Magnets Are Used in Smartwatches: A Deep Dive into Everyday Magnetics

Smartwatches have become an essential part of modern life. Whether it’s an Apple Watch, Samsung Galaxy Watch, or Garmin wearable, millions of people around the world strap them on daily to track their fitness, receive notifications, and even make payments. But what most people don’t realize is that magnets play a central role in how these devices function. From charging to haptic feedback, magnets power many of the unseen technologies behind your watch.

At Magfine, we specialize in neodymium magnets and other advanced magnetic solutions used across industries, including electronics, medical devices, and consumer wearables. This article explores how magnets are integrated into smartwatches, why they are crucial, and how this translates into broader applications across industries. If you are looking to source industrial magnets in Canada, this post will give you a technical yet accessible perspective.

Key Takeaway: Magnets in smartwatches are not just for charging—they enable alignment, vibration feedback, navigation sensors, strap systems, and more. Without precision-engineered magnets, smartwatches as we know them could not exist.

1. Magnetic Alignment in Wireless Charging

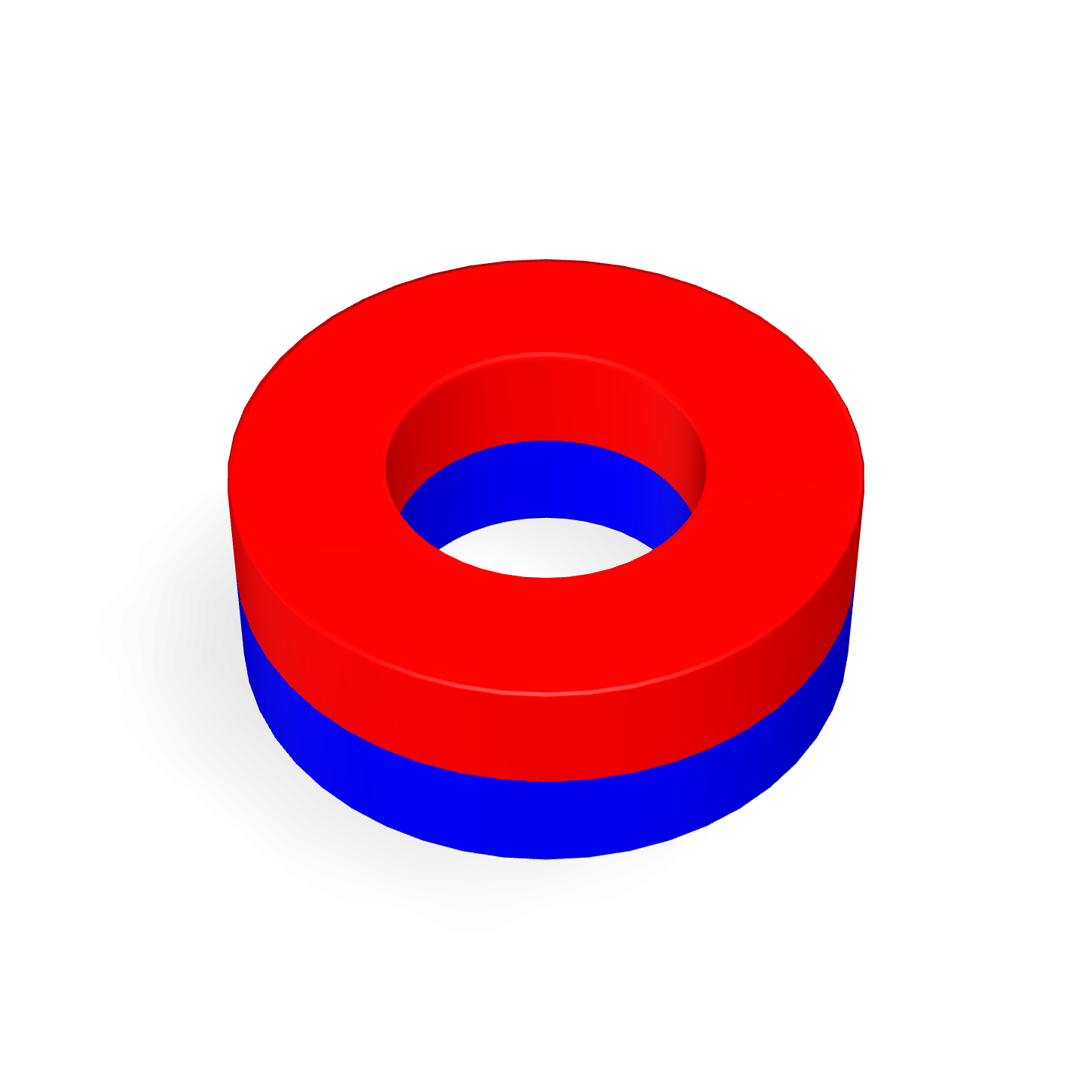

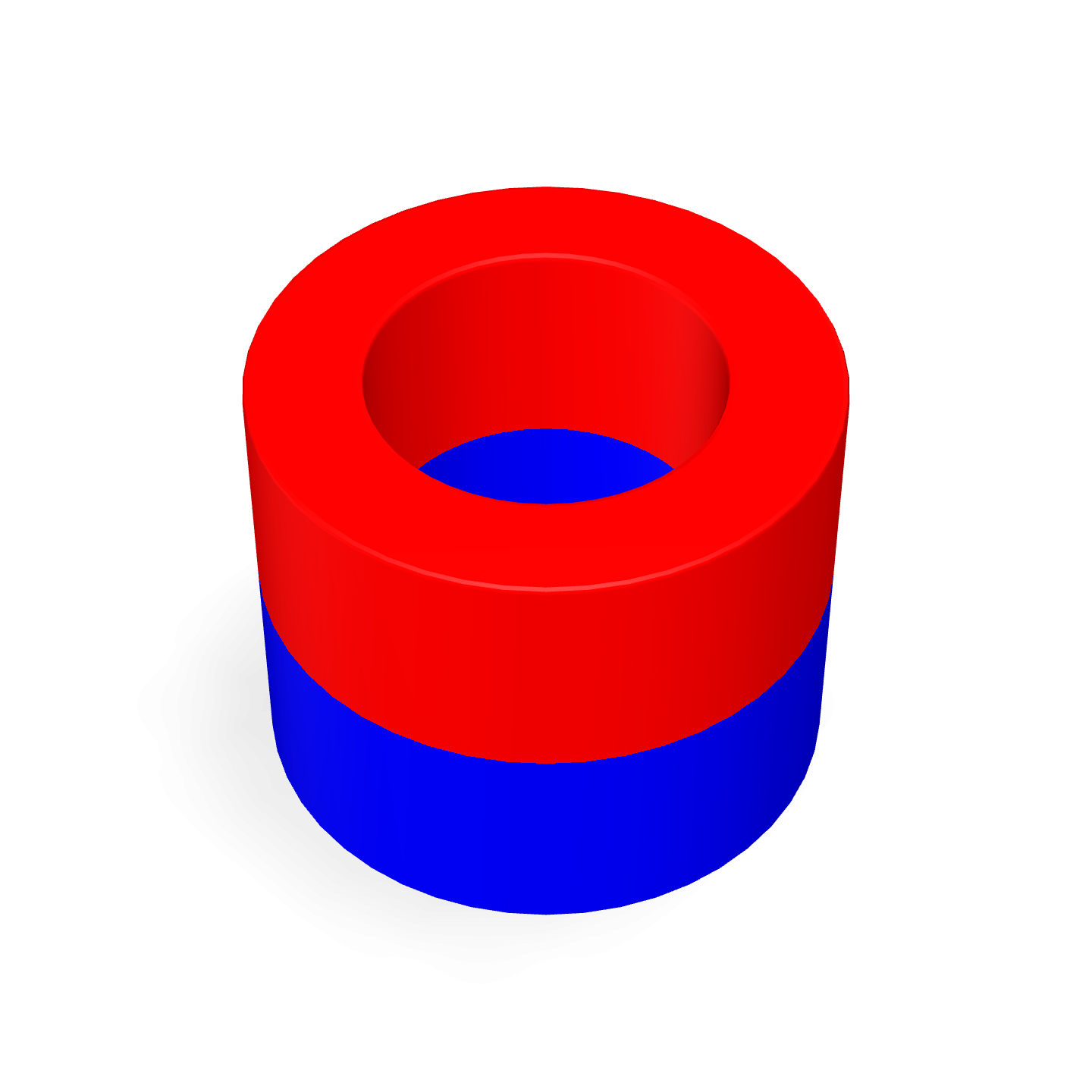

One of the most recognizable uses of magnets in smartwatches is during wireless charging. When you place your Apple Watch on its charging puck, you feel the device “snap” into place. This is not just for convenience—neodymium disc magnets inside the watch and charger ensure perfect alignment between the charging coil in the watch and the transmitting coil in the base.

This alignment is critical for inductive charging to work efficiently. If the coils are misaligned, energy transfer becomes less effective, leading to slower charging and increased heat. The magnets act as a guiding mechanism, maintaining consistent contact and optimizing the charging process.

For companies manufacturing wearable charging systems, sourcing high-quality neodymium magnets is essential to ensure reliable alignment. These magnets are compact but extremely powerful, making them perfect for confined spaces in consumer electronics.

2. The Role of Magnets in Haptics and Vibration Feedback

Apple markets its vibration system as the “Taptic Engine,” but at its core, it is a voice coil actuator—a system built on magnetism. When current flows through a coil positioned around a permanent magnet, it generates linear motion. This motion translates into precise taps on your wrist.

Unlike traditional vibration motors that spin a weight, this magnet-and-coil design allows for incredibly fine control. That’s why you can distinguish between a text notification and a navigation prompt—the feedback is subtle but distinct. Without the permanent magnet inside, this experience would not be possible.

In industrial settings, similar voice coil actuators using neodymium magnets are applied in robotics and automation, showing the crossover between consumer wearables and heavy-duty technologies.

3. Navigation and Magnetometer Integration

Modern smartwatches also feature built-in compasses. This is achieved through a magnetometer, a sensor that detects Earth’s magnetic field. Combined with accelerometers and gyroscopes, the magnetometer provides orientation data for maps and navigation.

However, integrating a magnetometer into such a small device is challenging. The presence of other magnets—used for charging or strap attachment—can create interference. To solve this, manufacturers rely on shielding materials such as soft magnetic alloys to isolate the sensors. The result: your smartwatch can still point north accurately even when magnets are built into its frame.

This is a prime example of how magnetic engineering expertise is required not just to supply magnets, but to integrate them effectively without disrupting other systems.

4. Magnetic Straps and Everyday Convenience

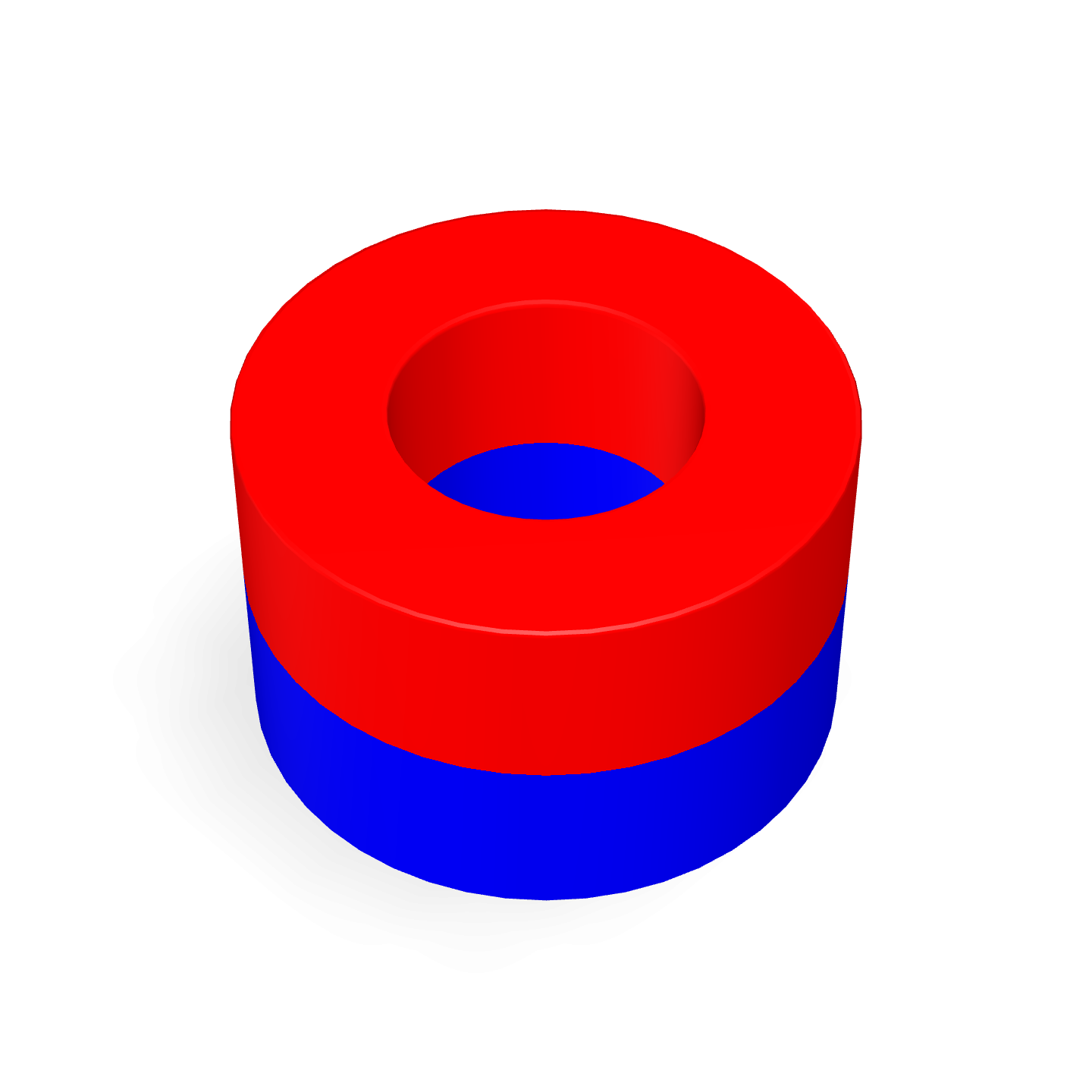

Many smartwatch bands, such as Apple’s Milanese Loop or Leather Link, use embedded magnets for easy fastening. These are not simple bar magnets but carefully designed multipole neodymium strips. By alternating north and south poles along the length of the band, manufacturers ensure the strap aligns smoothly and holds firmly without pinching the skin.

This clever use of magnets turns a functional requirement—keeping the watch on your wrist—into an elegant design solution. The same principle is used in magnetic closures for industrial enclosures, wearable medical devices, and even high-end consumer packaging.

5. Digital Crown and Magnetic Sensing

Another subtle use of magnets in the Apple Watch is the Digital Crown. This rotating knob uses a magnetic encoder system to detect precise rotation. Magnets interact with sensors inside the crown to measure its movement, which is then translated into digital input.

Unlike mechanical encoders, which rely on physical contact, magnetic encoders offer frictionless operation, reducing wear and extending the lifespan of the component. For a device that might be rotated thousands of times over its lifetime, this durability is critical.

6. Manufacturing Challenges of Magnets in Smartwatches

Designing magnets for wearables involves unique challenges:

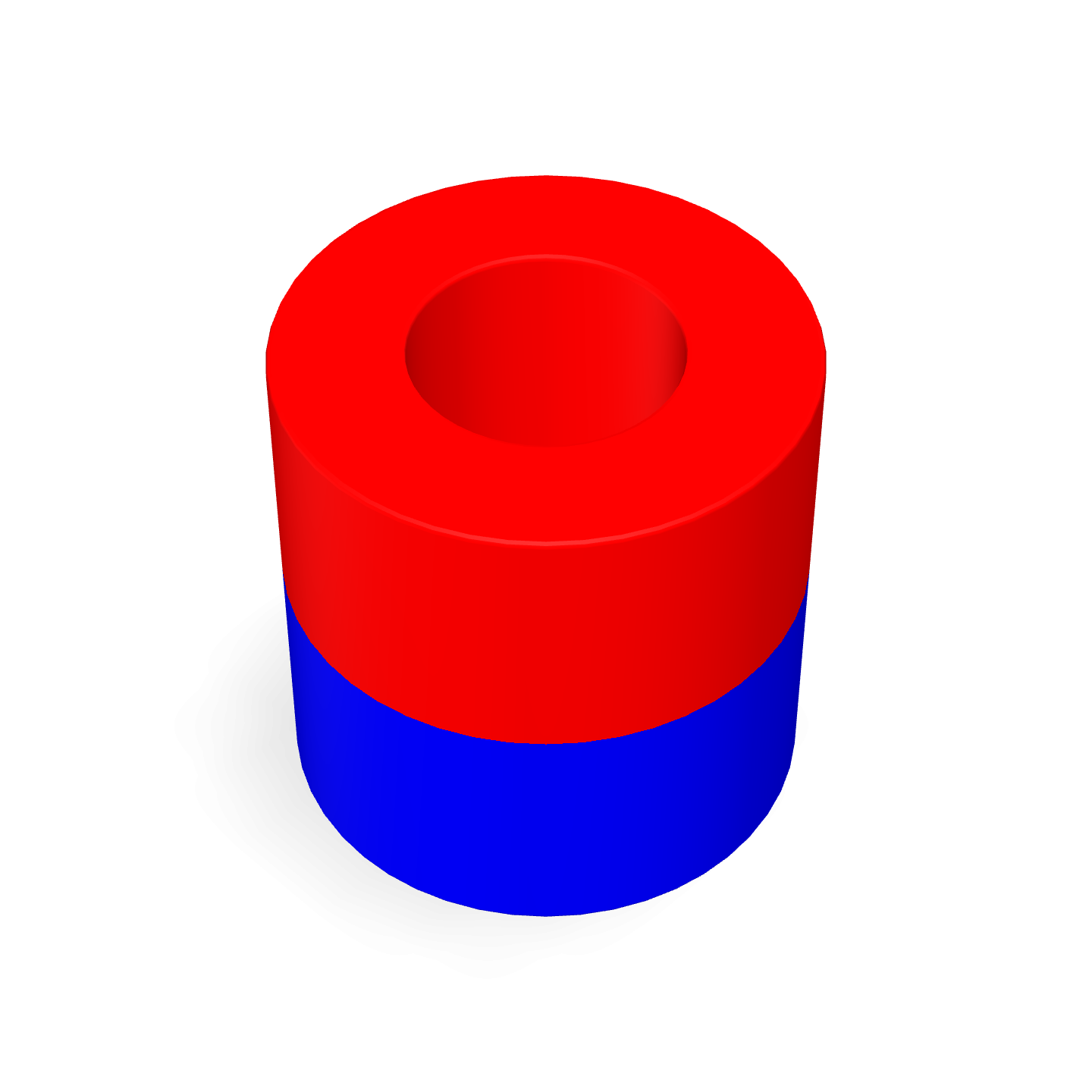

- Size constraints: Magnets must be incredibly small yet powerful, which is why neodymium magnets are preferred.

- Corrosion resistance: Since watches are exposed to sweat and water, magnets are coated with nickel-copper-nickel or epoxy to prevent rusting.

- Magnetic shielding: Stray magnetic fields must be contained to avoid interference with health sensors and wireless communication systems.

- Thermal stability: Magnets must maintain performance despite heat generated during charging or daily wear.

These factors highlight why partnering with a trusted supplier like Magfine is essential. From consumer electronics to industrial magnets, sourcing reliable materials ensures product longevity and customer satisfaction.

7. Applications Beyond Smartwatches

While this article focuses on wearables, the principles apply far beyond. The same magnet technologies are used in:

- Medical devices (magnetically fastened implants, drug delivery systems)

- Robotics (precision actuators and magnetic encoders)

- Industrial automation (contactless sensing, magnetic clutches)

- Consumer electronics (laptops, earbuds, and smartphones)

In every case, the performance of the system depends on the quality of the magnet chosen. That’s why industries across Canada turn to Magfine for advanced industrial magnet solutions.

Smartwatch Magnets Q&A

Q1: What type of magnets are used in smartwatches?

Smartwatches primarily use neodymium magnets. These are the strongest type of permanent magnet available, allowing for high performance in compact sizes.

Q2: Do magnets interfere with smartwatch sensors?

They can, but engineers use magnetic shielding materials to prevent interference with magnetometers, ECG sensors, and wireless communication systems.

Q3: Why are magnets used for watch bands?

Magnets make it easy to secure and adjust straps without buckles. Multipole patterns in neodymium strips ensure strong, comfortable fastening.

Q4: Can I buy neodymium magnets in Canada for my own projects?

Absolutely. At Magfine, we supply a wide range of magnets in Canada, from small disc magnets for electronics to heavy-duty industrial magnets for manufacturing.

Q5: How long do smartwatch magnets last?

Permanent magnets such as neodymium have an extremely long lifespan, often retaining most of their magnetism for decades if protected from corrosion and extreme heat.