DIY & Hobbyist Magnet Projects: How to Safely Use Neodymium Magnets at Home

Neodymium magnets are a favorite among DIY makers and hobbyists for their strength and versatility. This guide takes a step-by-step approach, covering how to select, handle, and use these magnets safely while providing practical tips and project ideas that hobbyists will find useful. Keywords like "DIY magnet projects," "neodymium magnet safety," and "hobby magnets" are naturally included for easier discovery by search engines.

1. Understanding Neodymium Magnets

Neodymium magnets, also called NdFeB or rare-earth magnets, are made from an alloy of neodymium, iron, and boron. They are among the strongest permanent magnets available. This strength allows small magnets to hold or attract large loads, making them ideal for various DIY and hobbyist projects such as magnetic closures, model-making, robotics, and interactive art.

Because of their power, neodymium magnets must be handled carefully to avoid injury or damage.

2. Selecting the Right Magnet

Grade and Strength

Magnets come in different grades, like N35, N42, or N52, which indicate their maximum strength. Higher grades are stronger, but using a magnet stronger than needed increases risk without adding benefit.

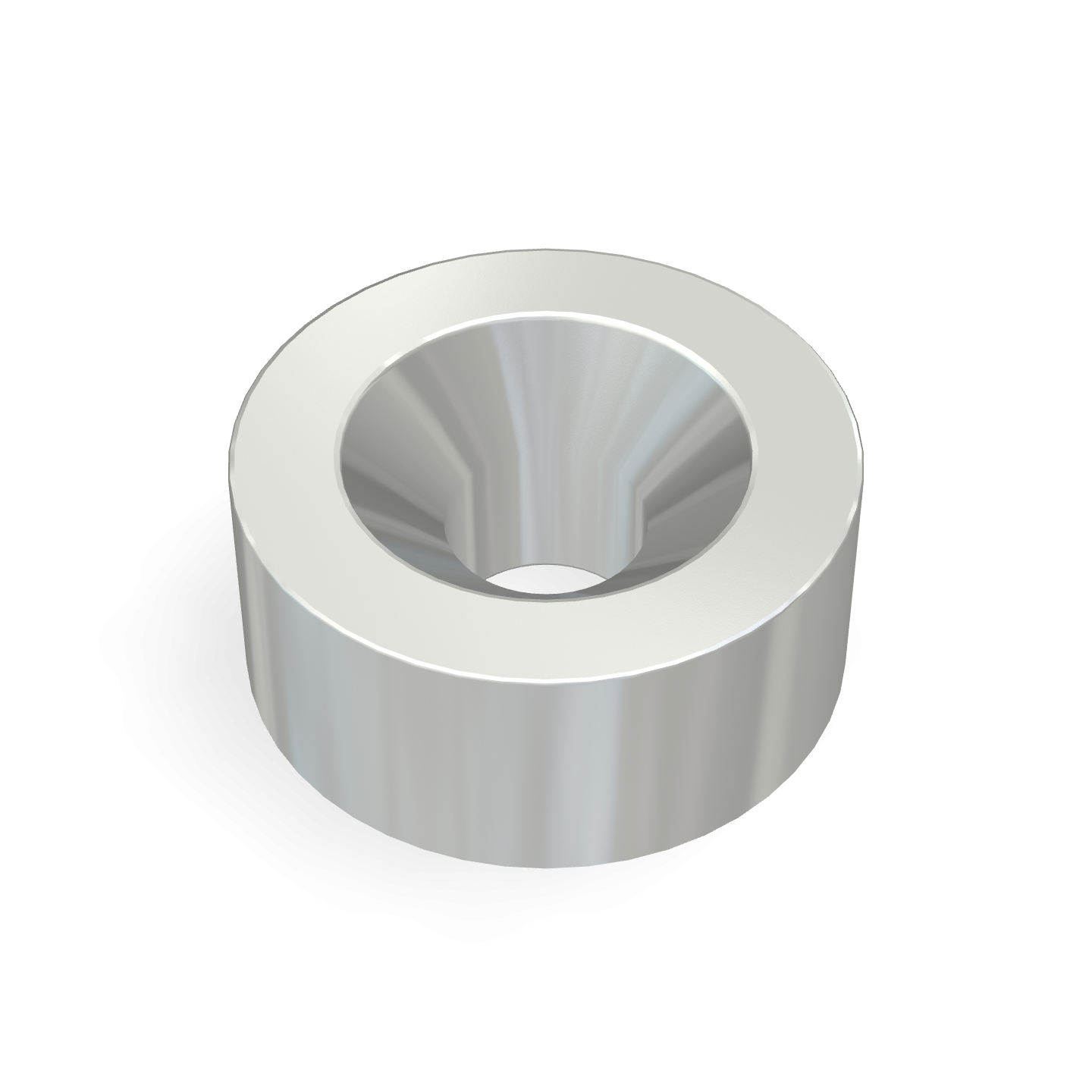

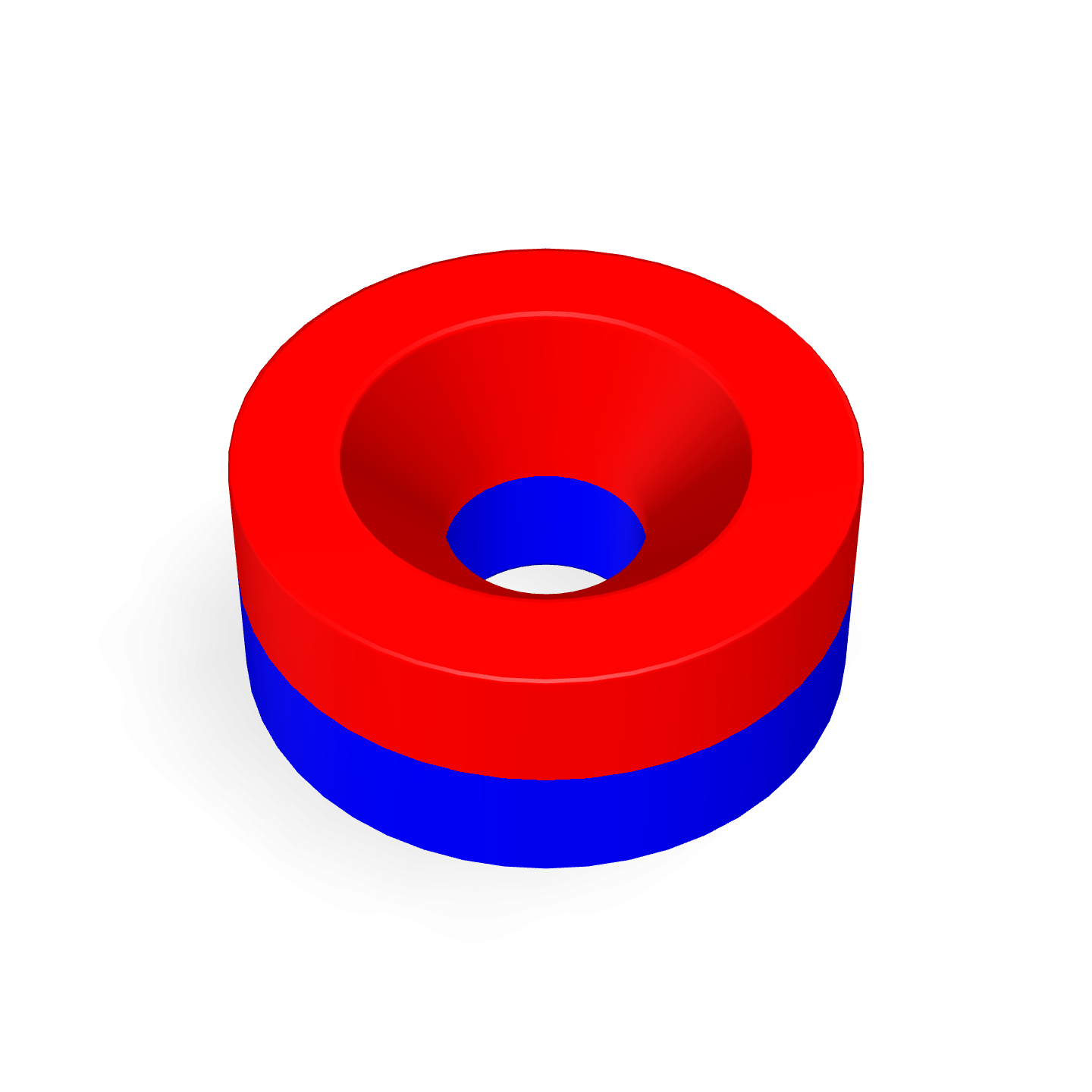

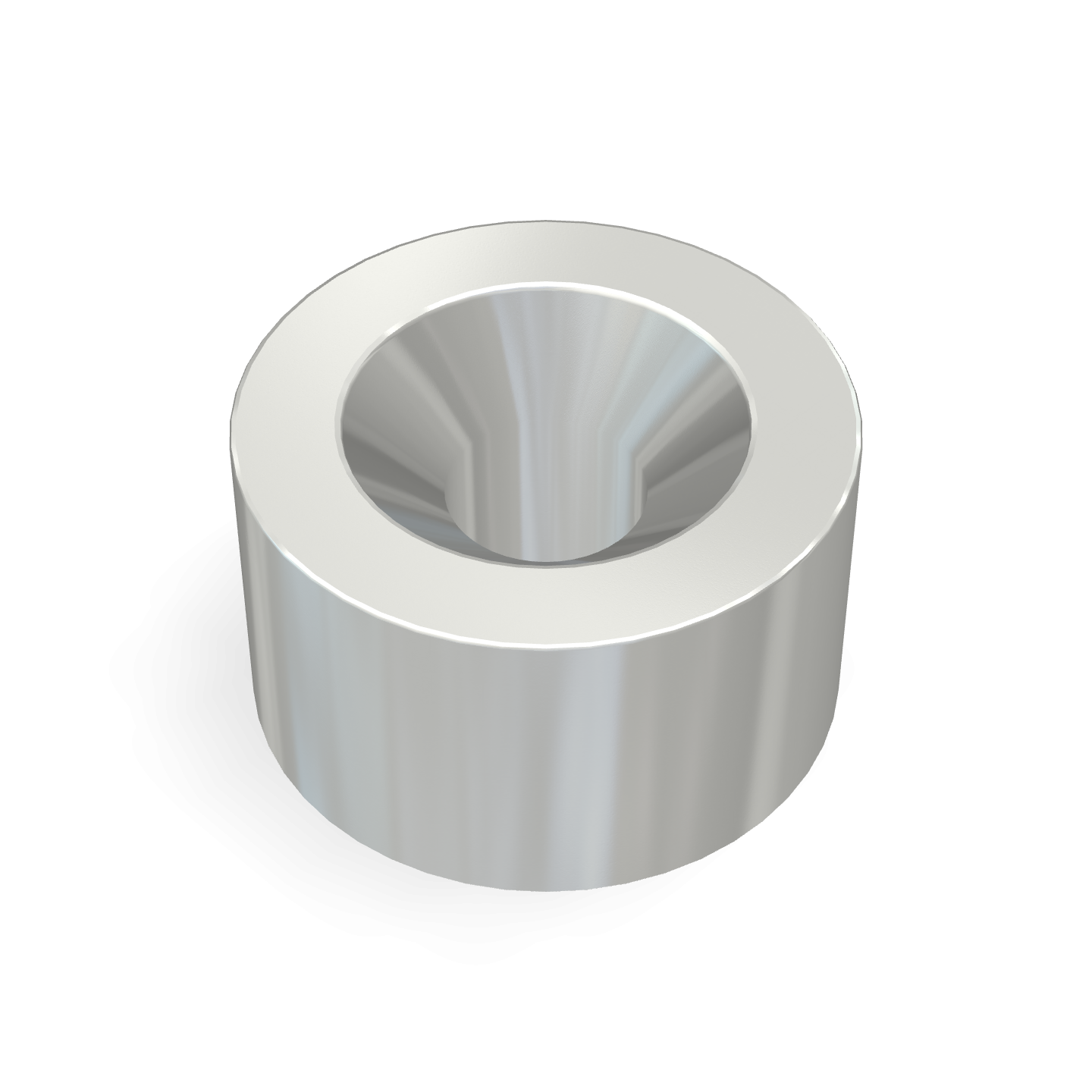

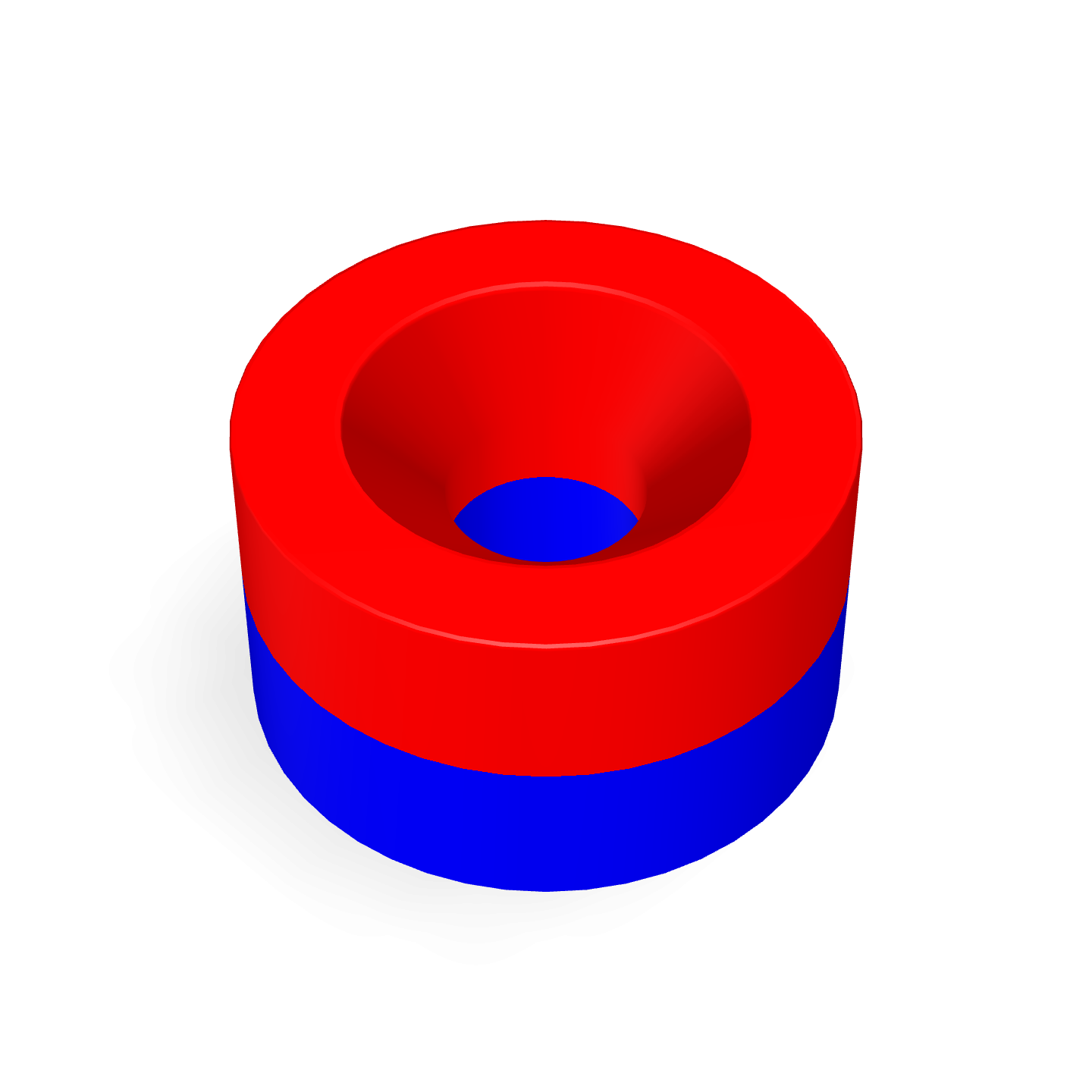

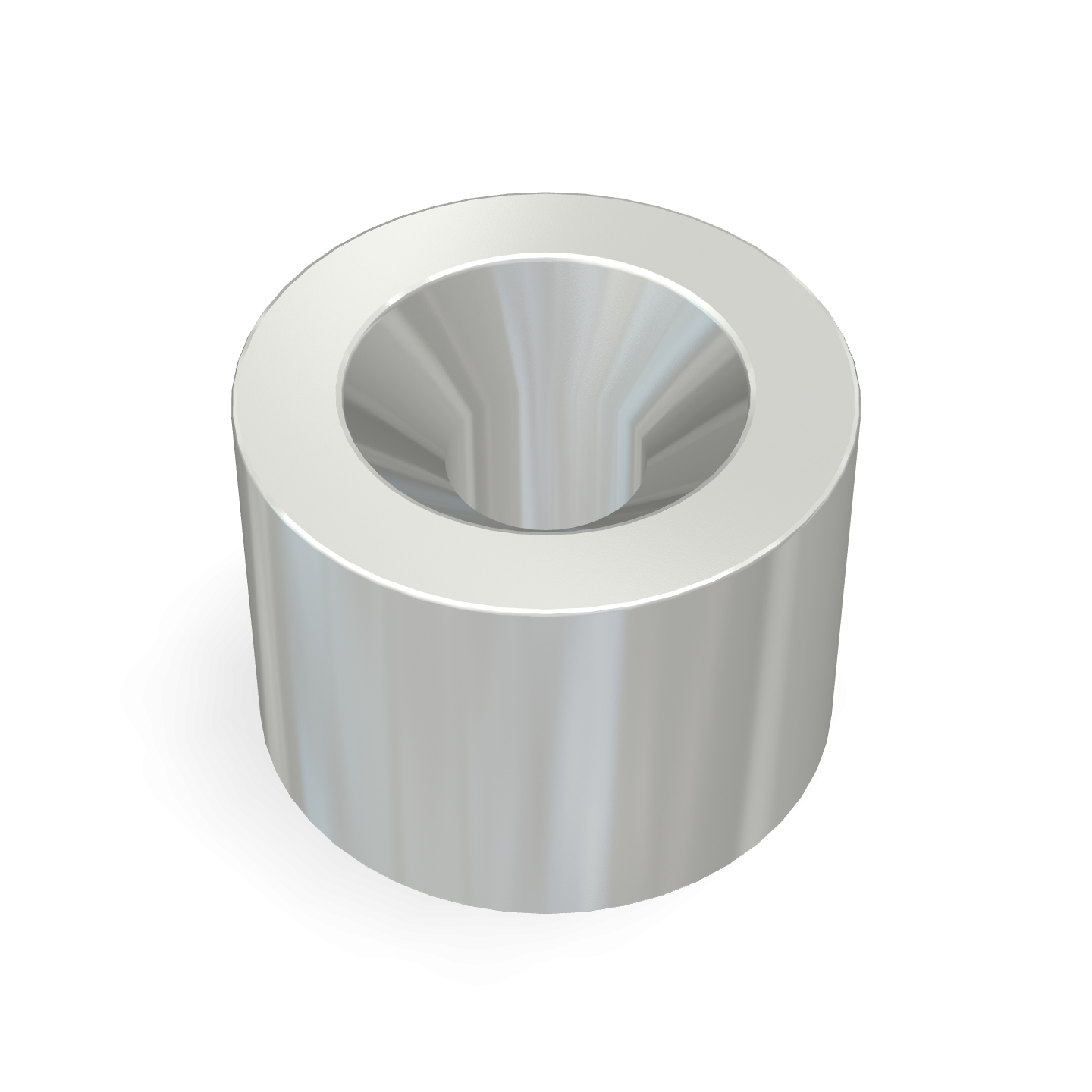

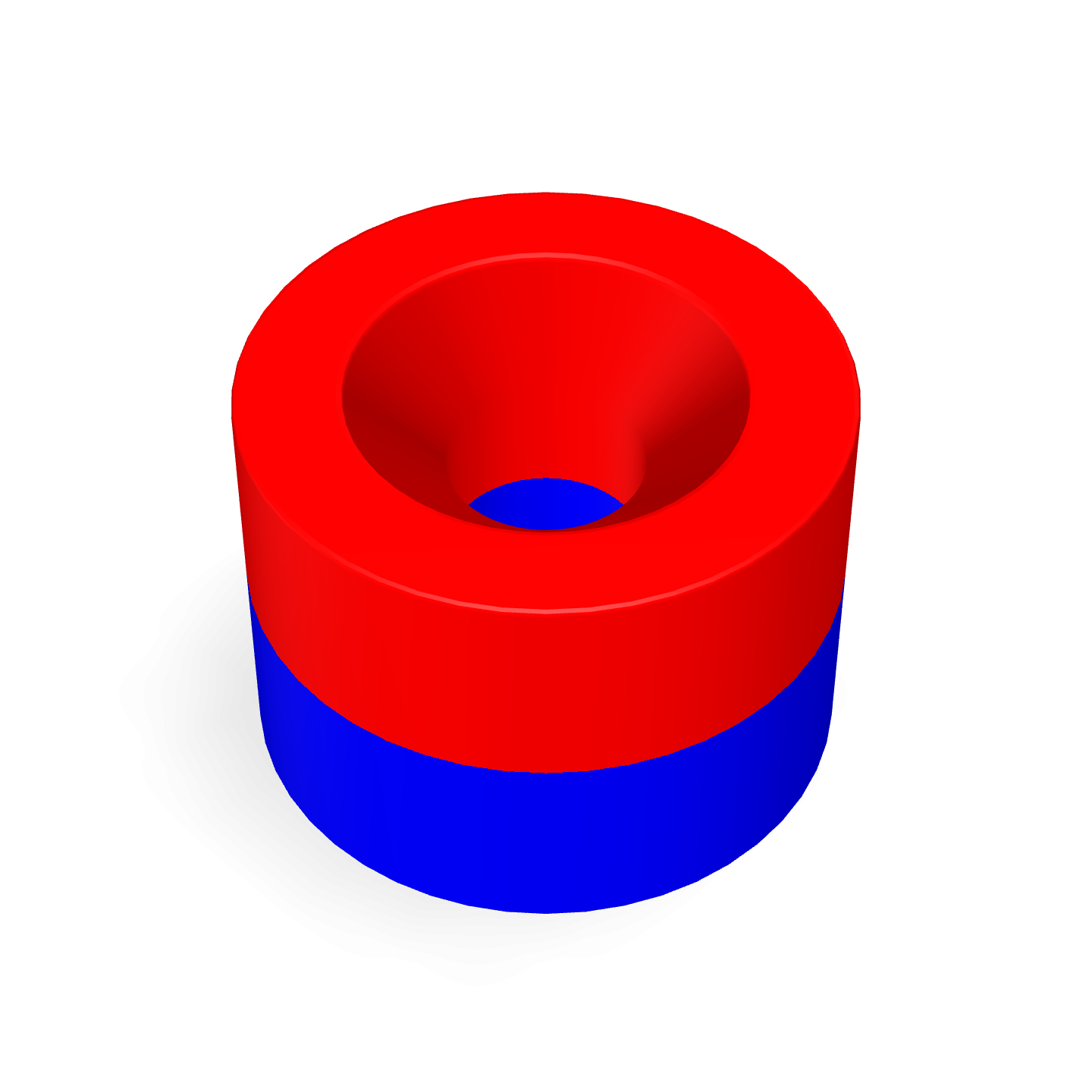

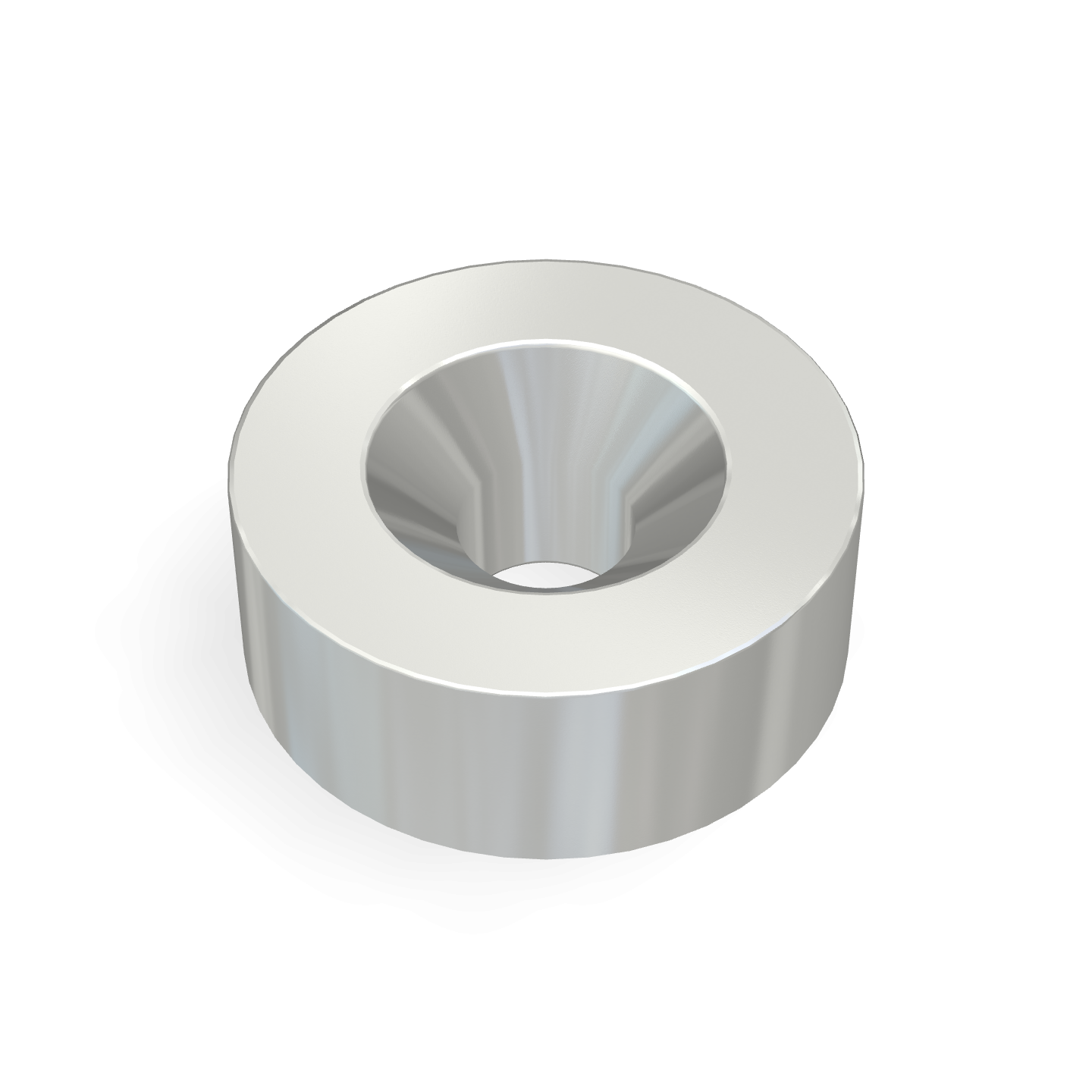

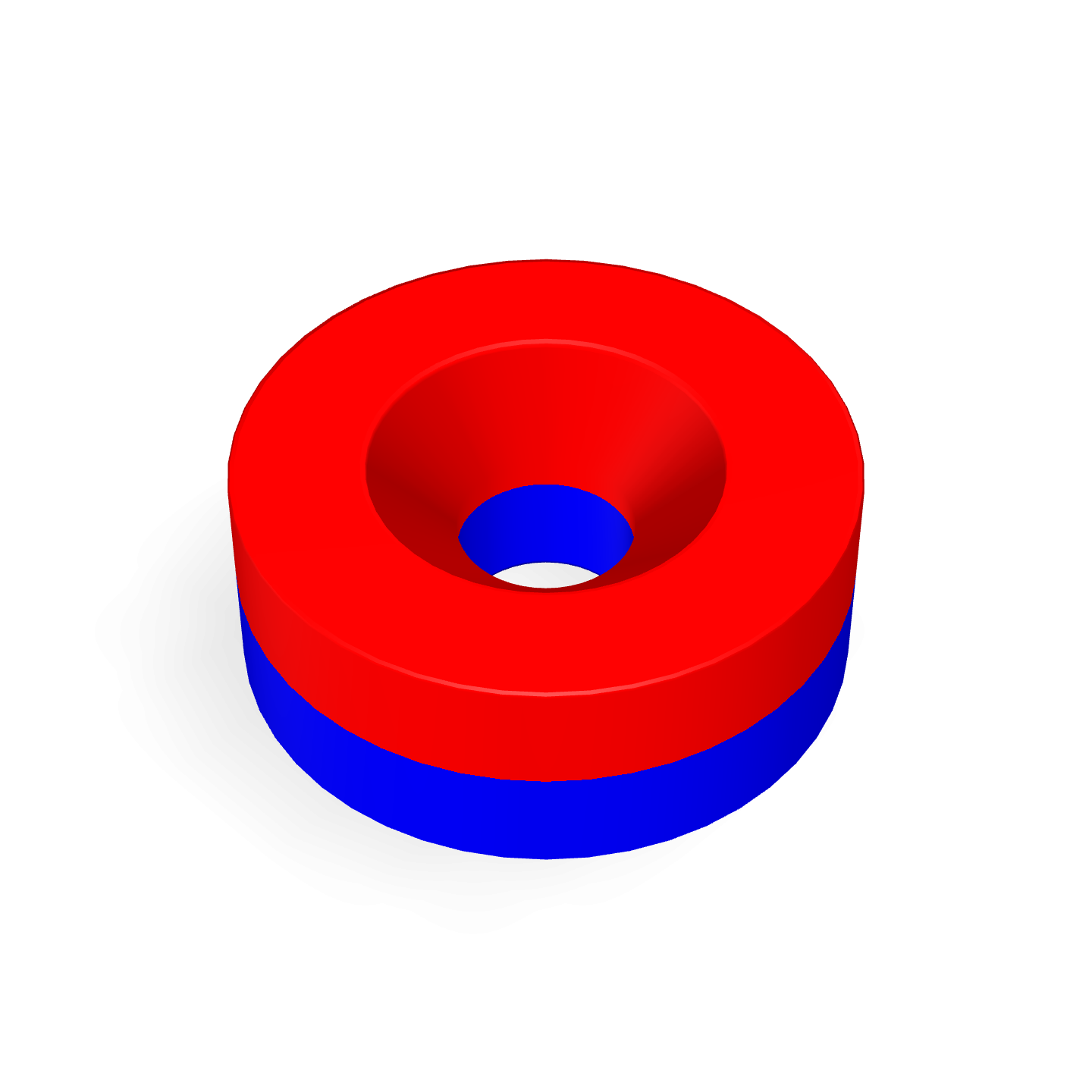

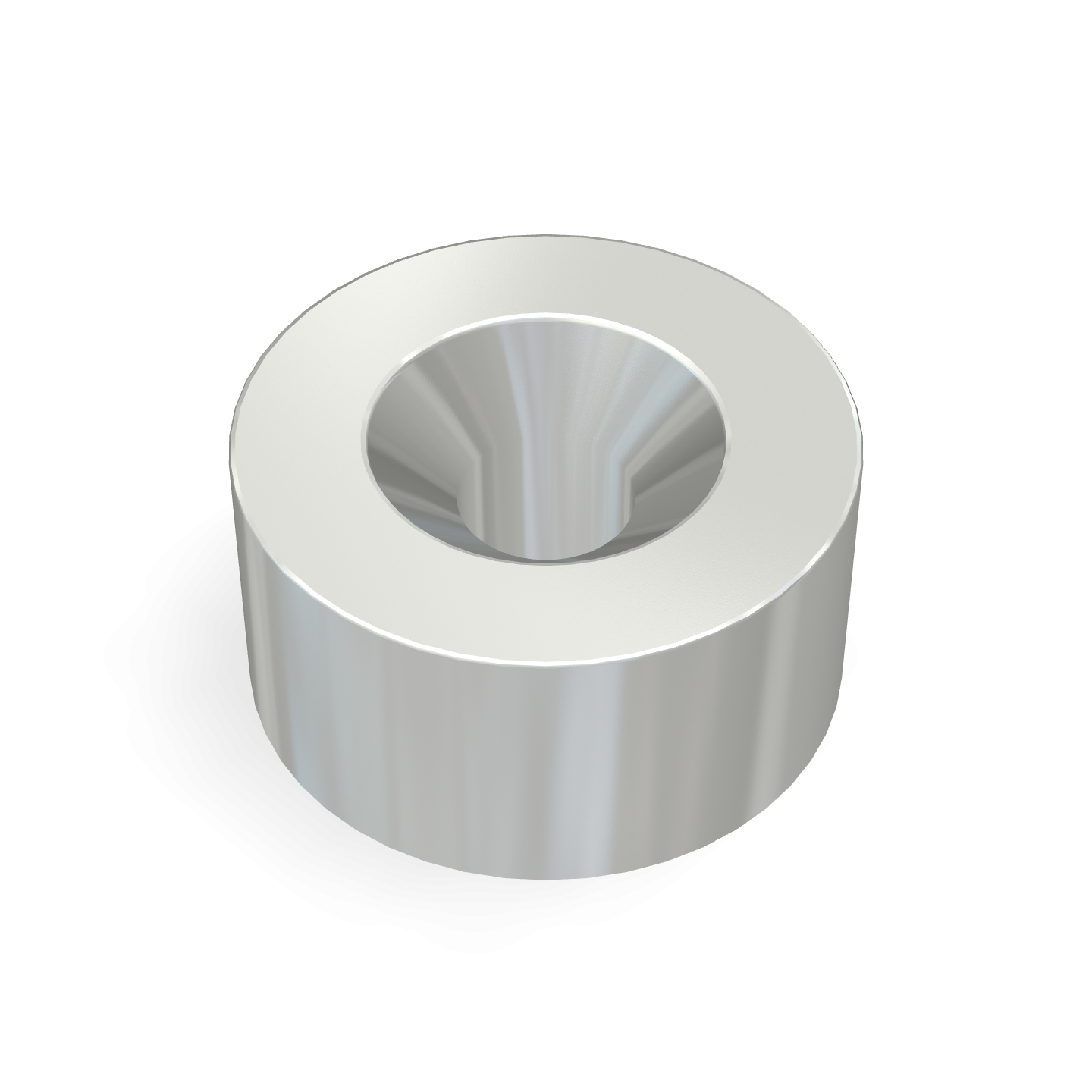

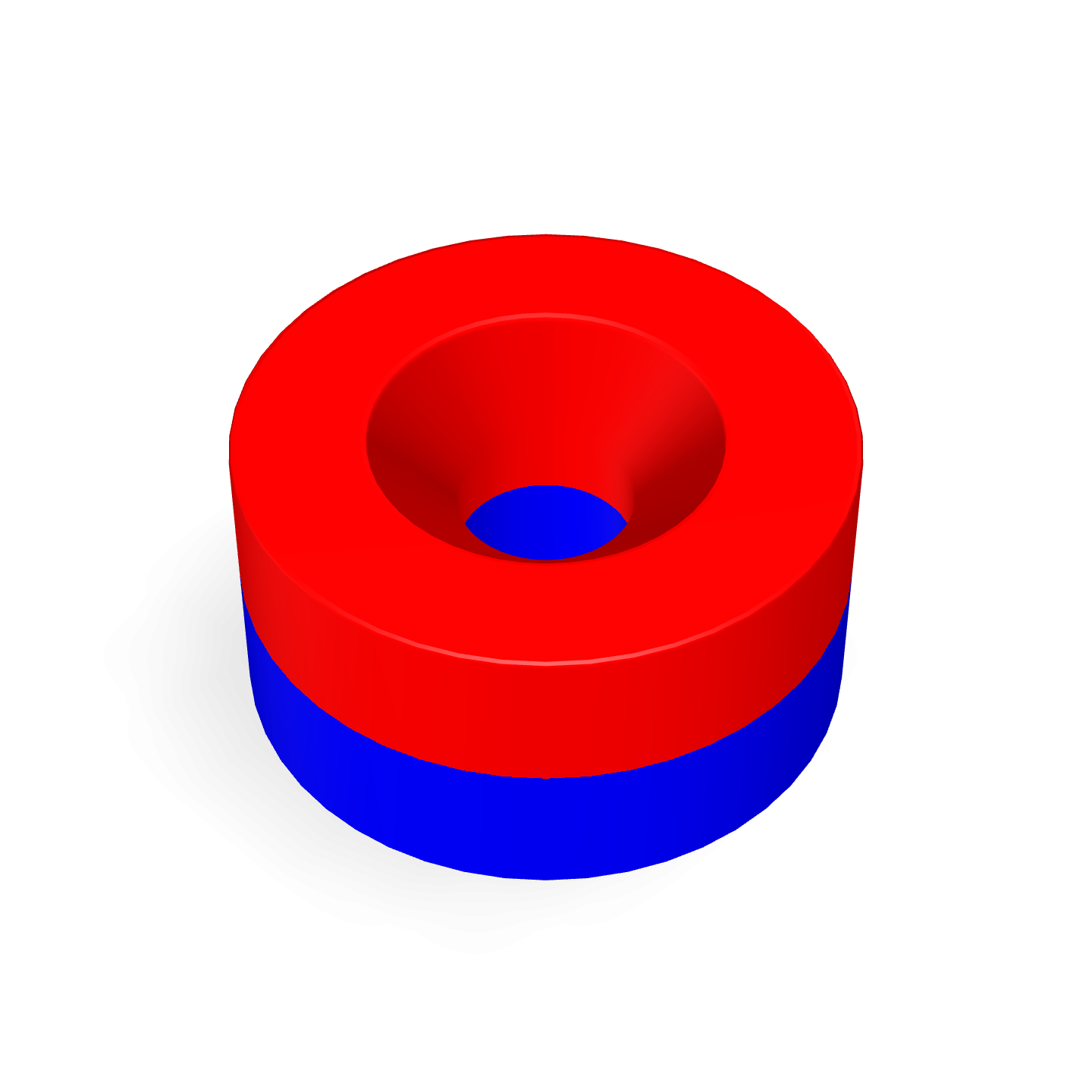

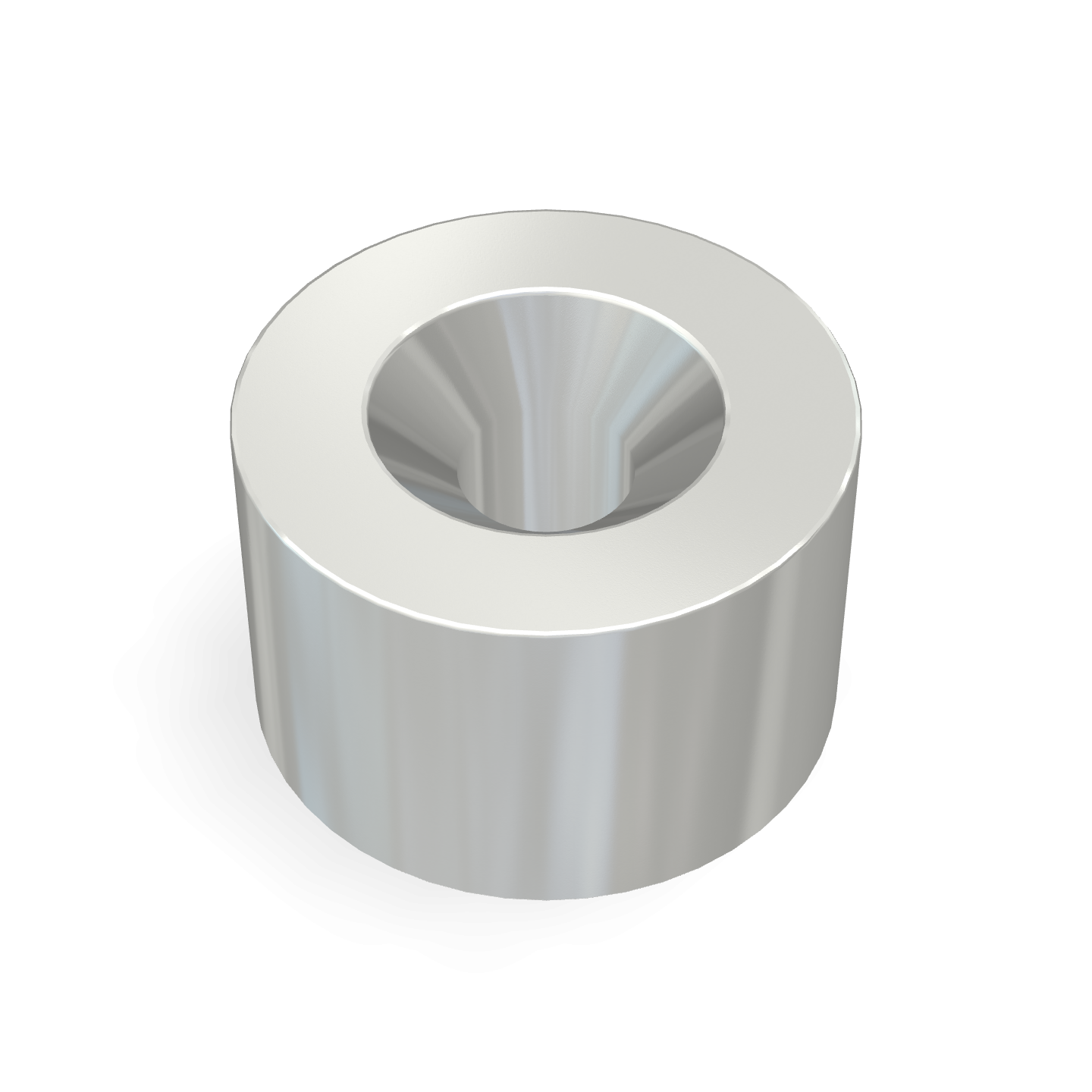

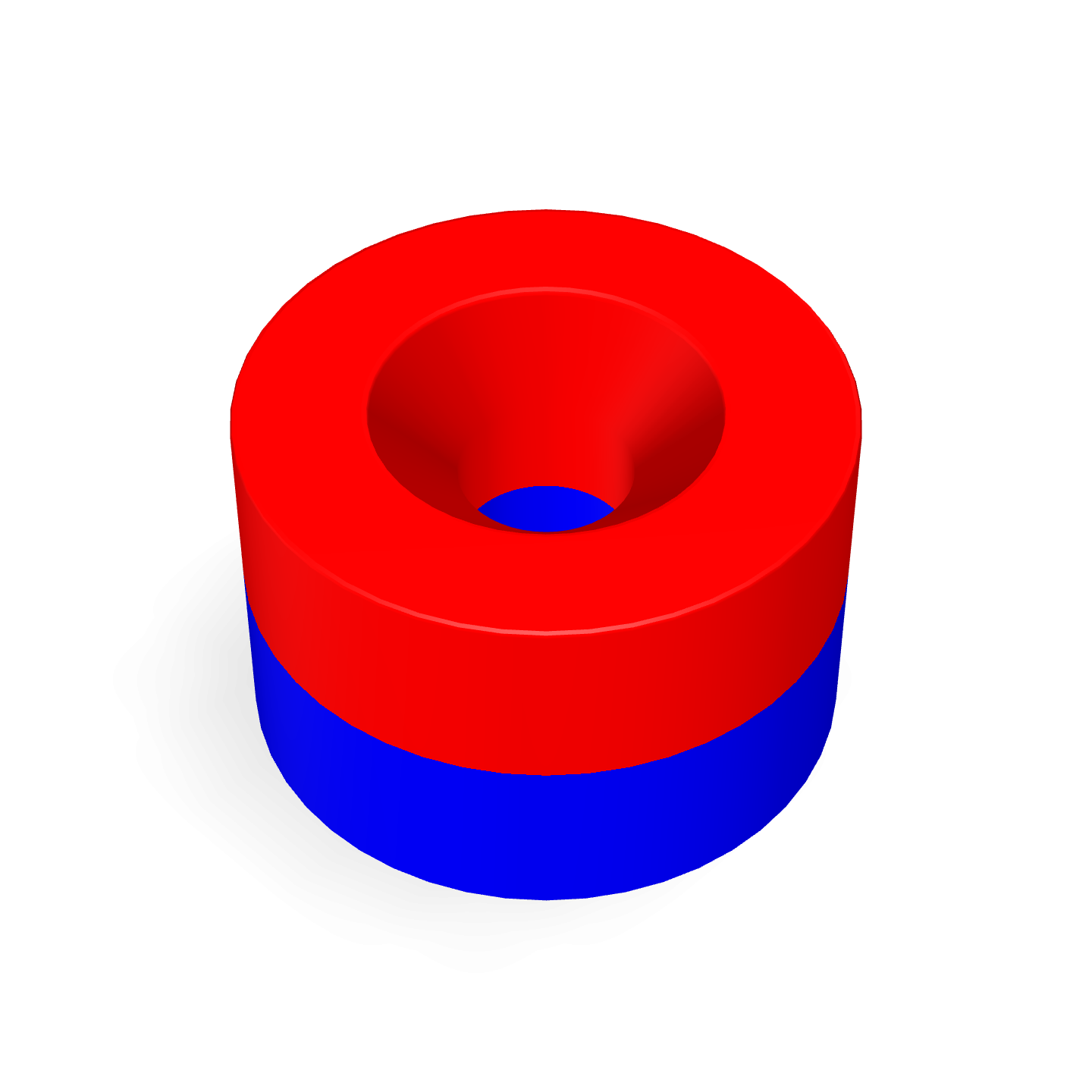

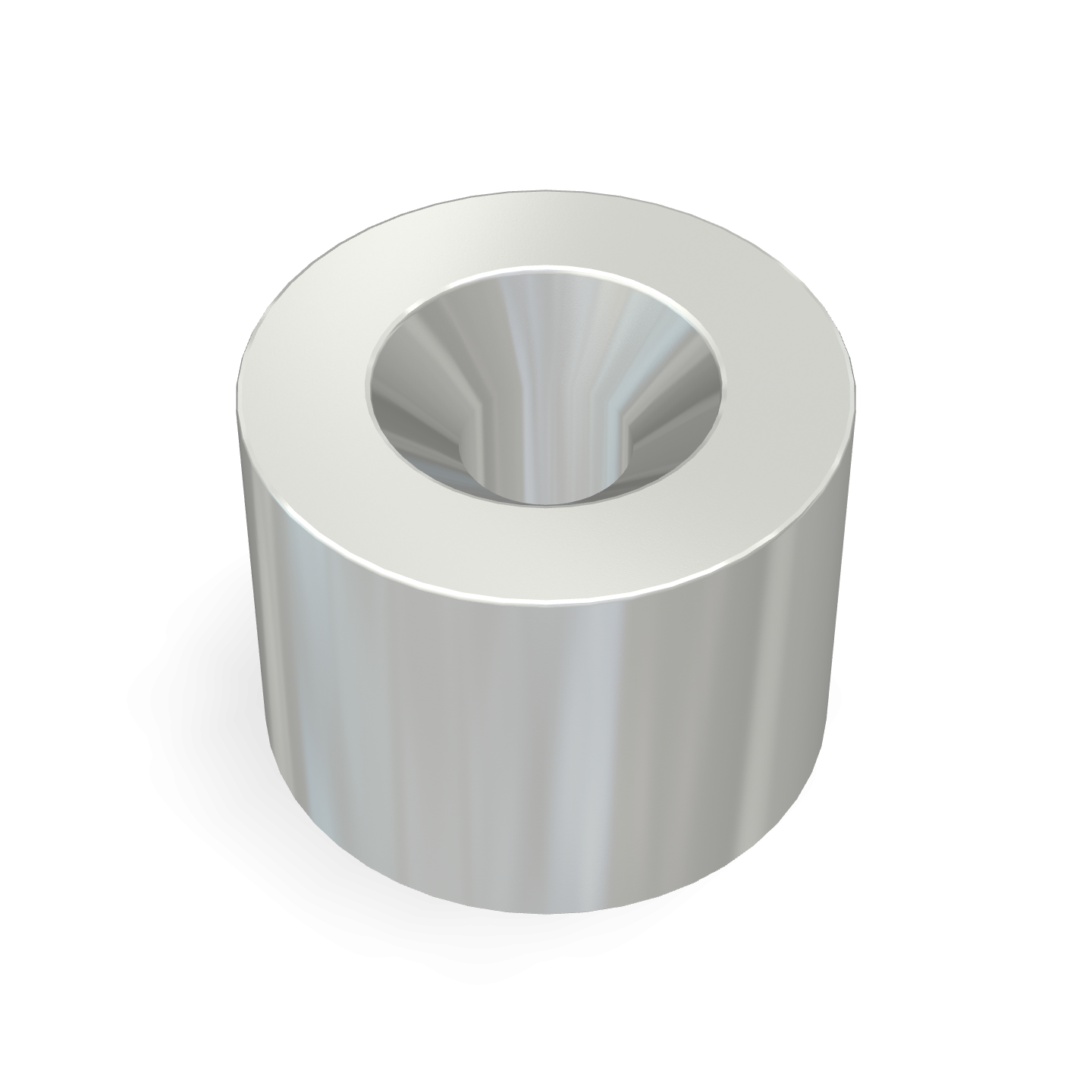

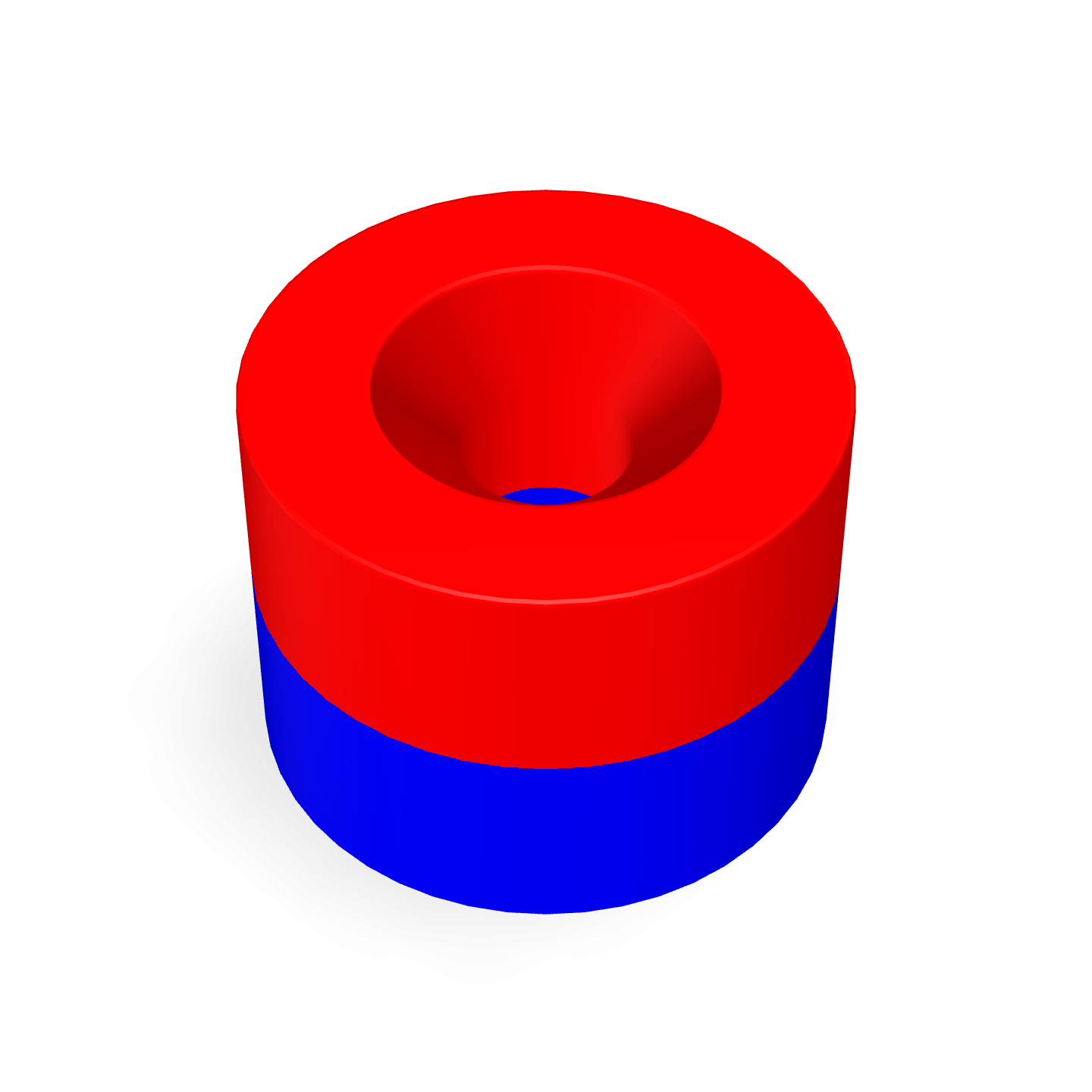

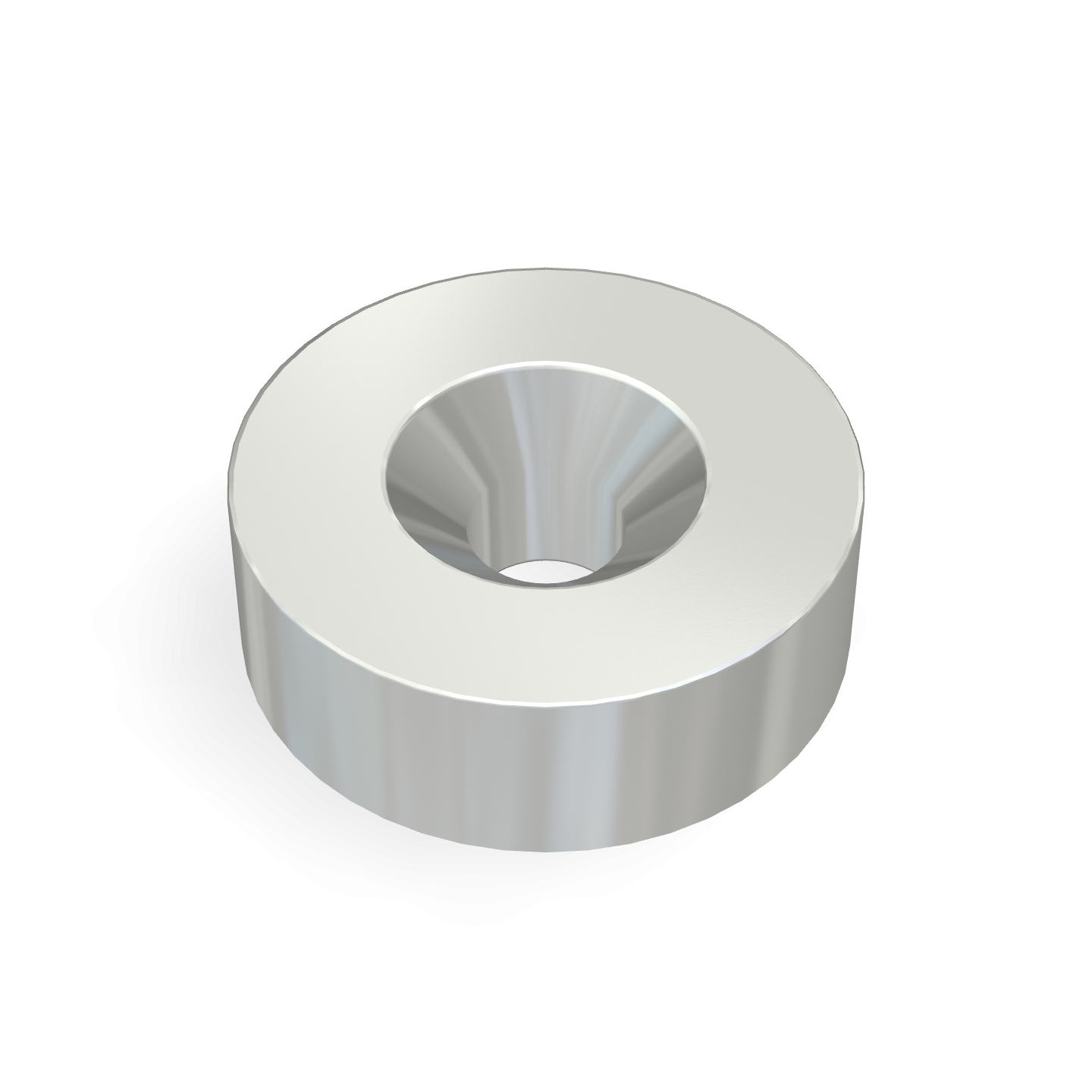

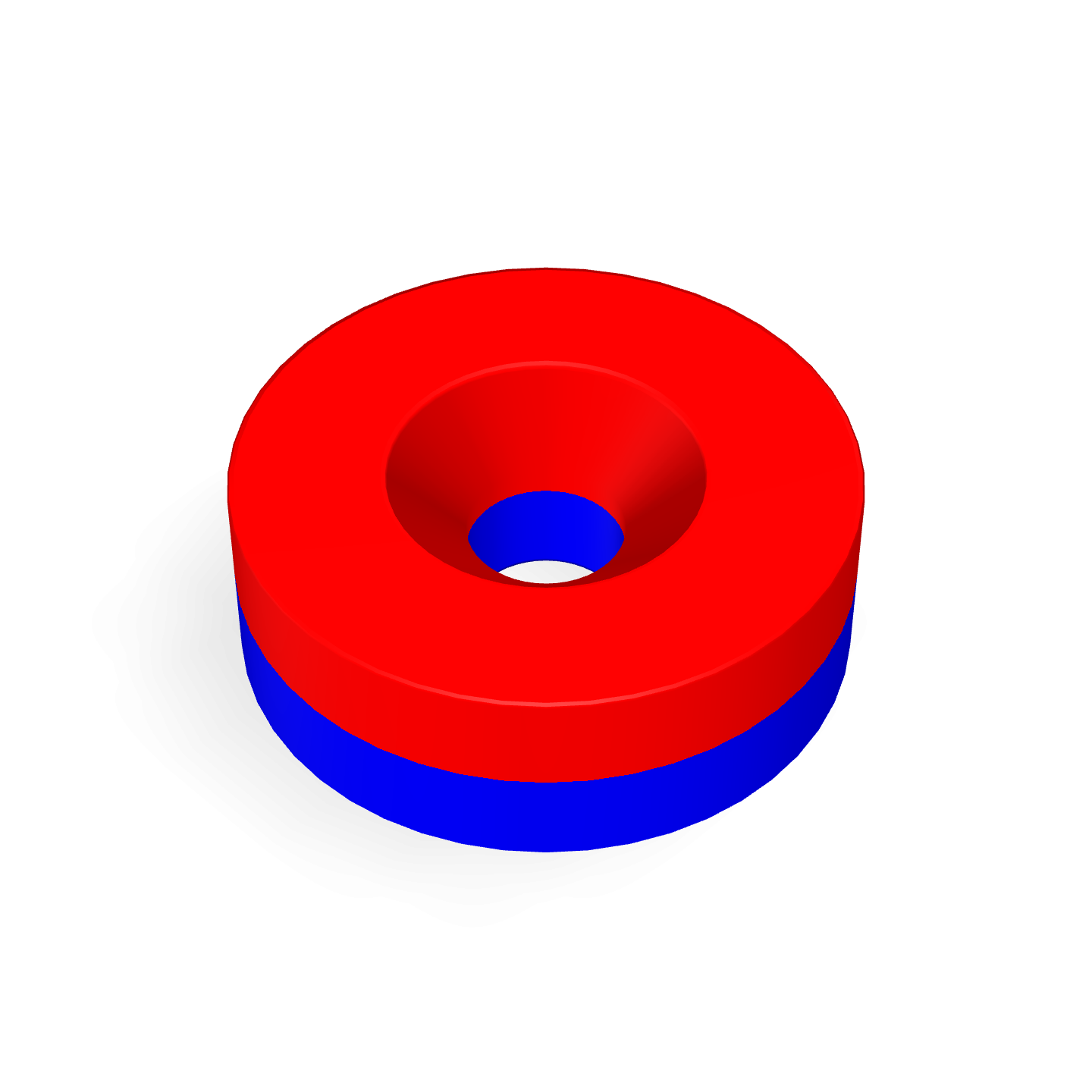

Shape and Mounting

Common shapes include discs, blocks, rings, and spheres. Some come with countersunk holes for mounting, while others have protective coatings. Choosing the right shape and mounting option ensures stability and effectiveness in your project.

Coating and Environment

Neodymium magnets are prone to corrosion and brittleness if left bare. Nickel-copper-nickel plating or rubber coating can protect them, especially if they will be exposed to moisture or used outdoors.

Project Fit

Select a magnet size and strength appropriate for your project. Ensure that the pull force is sufficient for the load and that mounting arrangements reduce risk of detachment or accidental attraction.

3. Safety Tips for Handling and Storage

Pinch and Impact Hazards

Strong magnets can attract metal surfaces rapidly. Fingers, skin, and tools can get pinched. Wear protective gloves when handling larger magnets and approach them slowly when separating.

Fragmentation and Eye Protection

Neodymium magnets are brittle. If they collide, they can chip or shatter, sending fragments at high speed. Always wear safety glasses during installation or separation.

Interference with Electronics and Medical Devices

These magnets can affect pacemakers, credit cards, hard drives, and other electronics. Keep magnets away from medical devices and sensitive electronics.

Temperature and Corrosion

Neodymium magnets can lose strength above about 80 °C and corrode in humid conditions unless properly coated. Avoid machining magnets unless you have specialized tools, as dust is hazardous and machining can demagnetize them.

Storage

- Store magnets in a way that their fields cancel, such as alternating polarities.

- Use a shielded container or a box with sheet iron to reduce stray magnetic fields.

- Keep magnets away from electronics, cards, and medical devices.

- Ensure large magnets are stored safely to prevent accidental attraction or falling.

4. Planning and Executing a DIY Magnet Project

Step 1: Define Your Project

Identify what you want to achieve and the requirements, such as strength, size, exposure to elements, and type of attachment.

Step 2: Select Materials

Choose magnets with adequate grade, size, and coating. Gather mounting hardware, adhesives, and safety gear.

Step 3: Prototype

Test magnet placement, alignment, and strength using scrap materials to avoid surprises.

Step 4: Installation

Mount magnets carefully, ensuring alignment and stability. Use fixtures or jigs when necessary and check poles if arranging multiple magnets.

Step 5: Test and Evaluate

Check the magnet under normal and extreme conditions. Ensure there is no risk of detachment, accidental attraction, or interference with electronics.

Step 6: Maintenance

Regularly inspect magnets for wear, corrosion, or mounting issues. Replace or adjust as needed.

5. Project Ideas

- Magnetic tool board: Hold tools on a steel board with magnets mounted behind the surface.

- Magnetic couplings: Attach detachable components in RC vehicles or models.

- Levitation experiments: Create small floating objects with careful magnet arrangement.

- Magnetic closures: Design hidden compartments or cabinet doors that snap closed magnetically.

- Interactive art: Use magnets for pendulums, moving sculptures, or STEM demonstrations.

6. Frequently Asked Questions

Are neodymium magnets safe around children?

No. Small magnets can be swallowed, causing serious internal injuries. Keep them out of reach of children and pets.

Can I drill or machine neodymium magnets?

It is not recommended. Machining can cause chipping, dust hazards, and loss of magnetism. Use pre-manufactured shapes whenever possible.

How far should magnets be from electronics?

Keep strong magnets away from electronics and magnetic media, ideally at least one meter away, depending on strength.

Can neodymium magnets be used outdoors?

Only if coated or sealed for corrosion resistance. Standard magnets may lose strength or corrode in humid or wet conditions.

7. Key Takeaways

- Neodymium magnets are powerful tools for DIY and hobby projects.

- Select the right grade, size, shape, and coating for your project.

- Follow safety guidelines for handling, storage, and proximity to electronics or medical devices.

- Plan projects carefully and test before full installation.

- Regularly inspect and maintain magnets for long-term safety.

With thoughtful planning and safe practices, neodymium magnets can add creativity, functionality, and fun to your projects.