Radial Neodymium Ring Magnets: Precision Magnetic Performance for Modern Applications

When it comes to high-performance motors, sensor assemblies, and demanding magnetic systems, radial neodymium ring magnets offer a level of control and efficiency that conventional magnets can’t match. Whether you're an engineer, manufacturer, or hobbyist exploring the next-generation of magnet technology, understanding what radial magnets bring to the table can help you make smarter decisions.

In this post, we’ll dive into what makes radial neodymium ring magnets so unique, how they differ from standard rings, where they are used, and why Magfine.ca is your go-to supplier for industrial magnets in Canada.

What is a Radial Neodymium Ring Magnet?

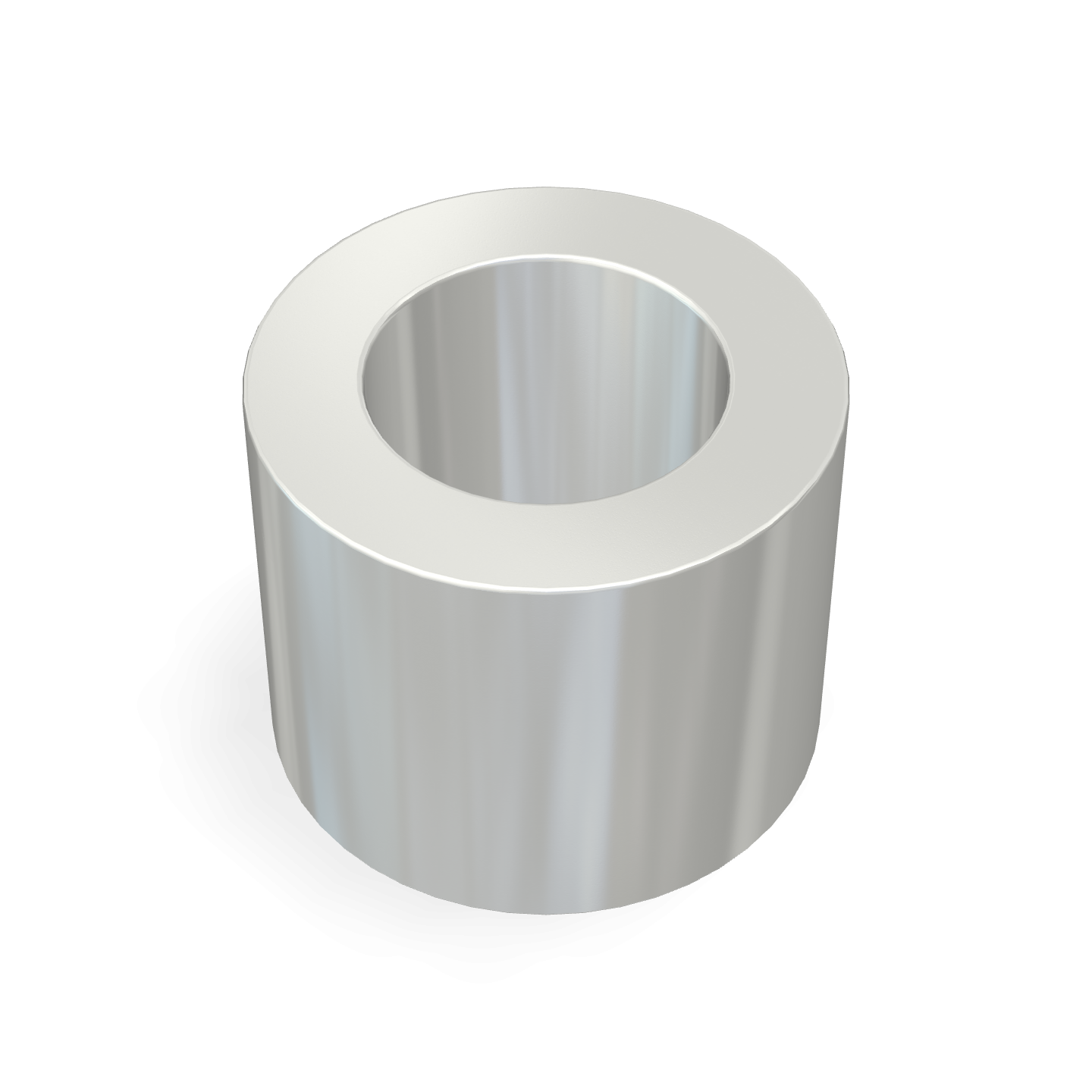

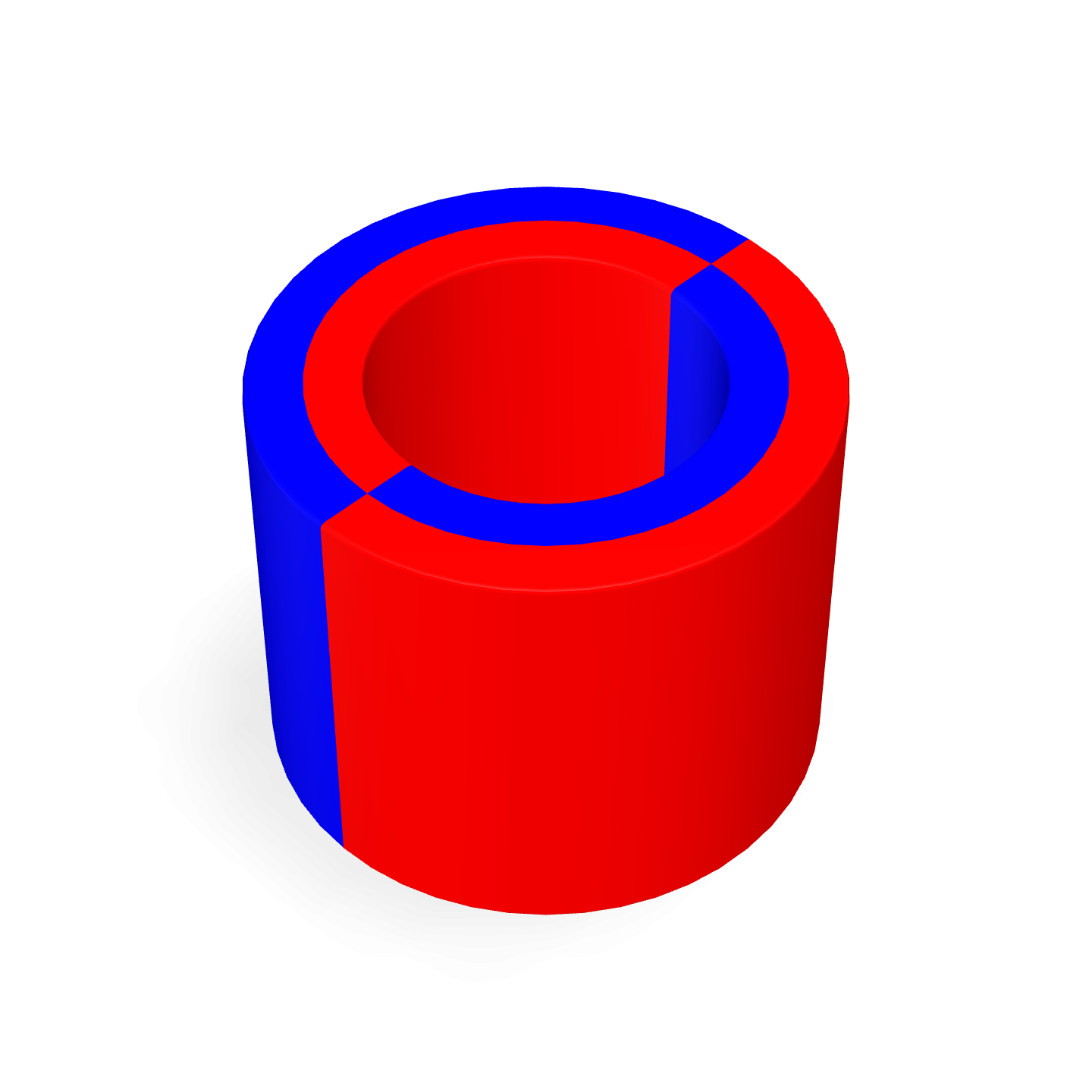

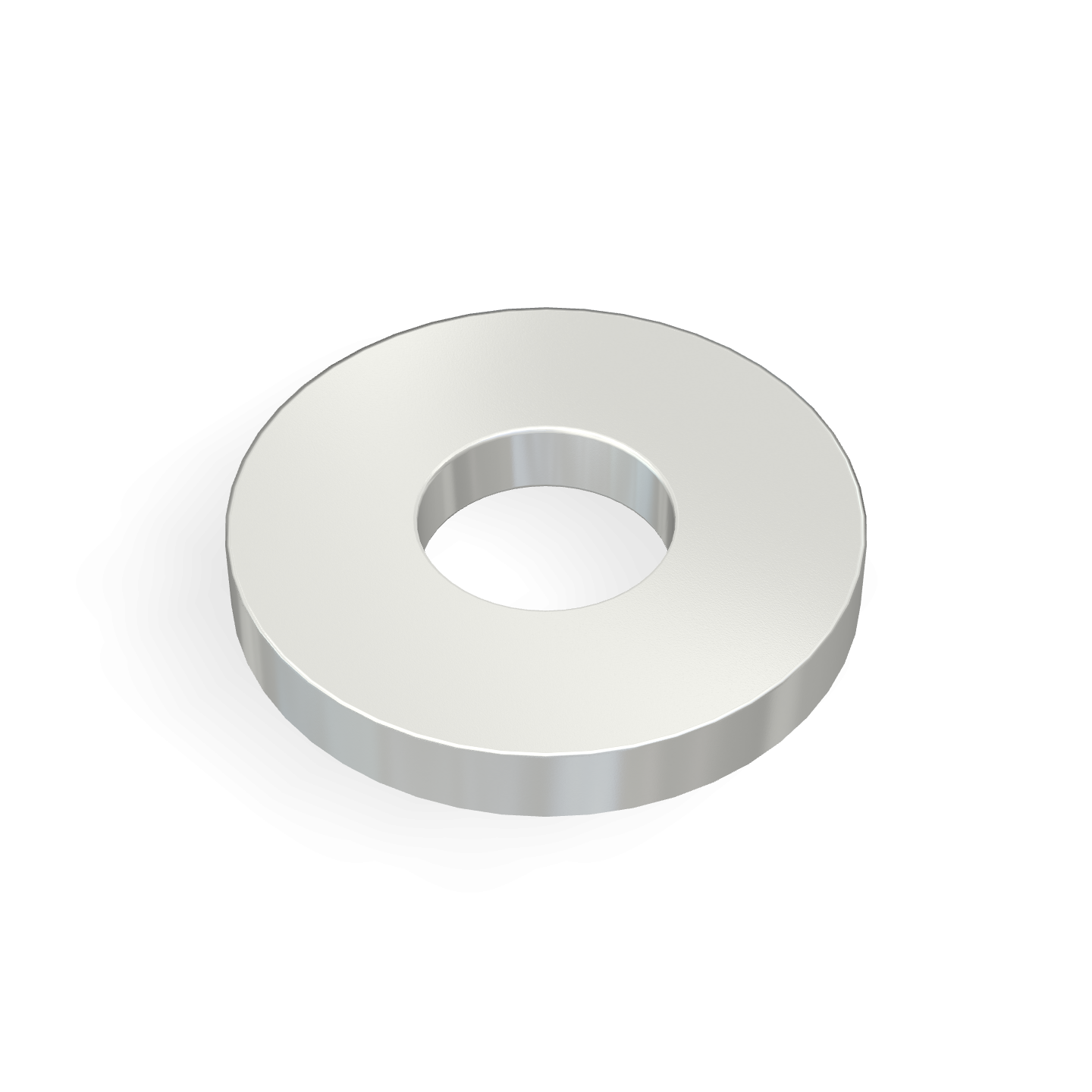

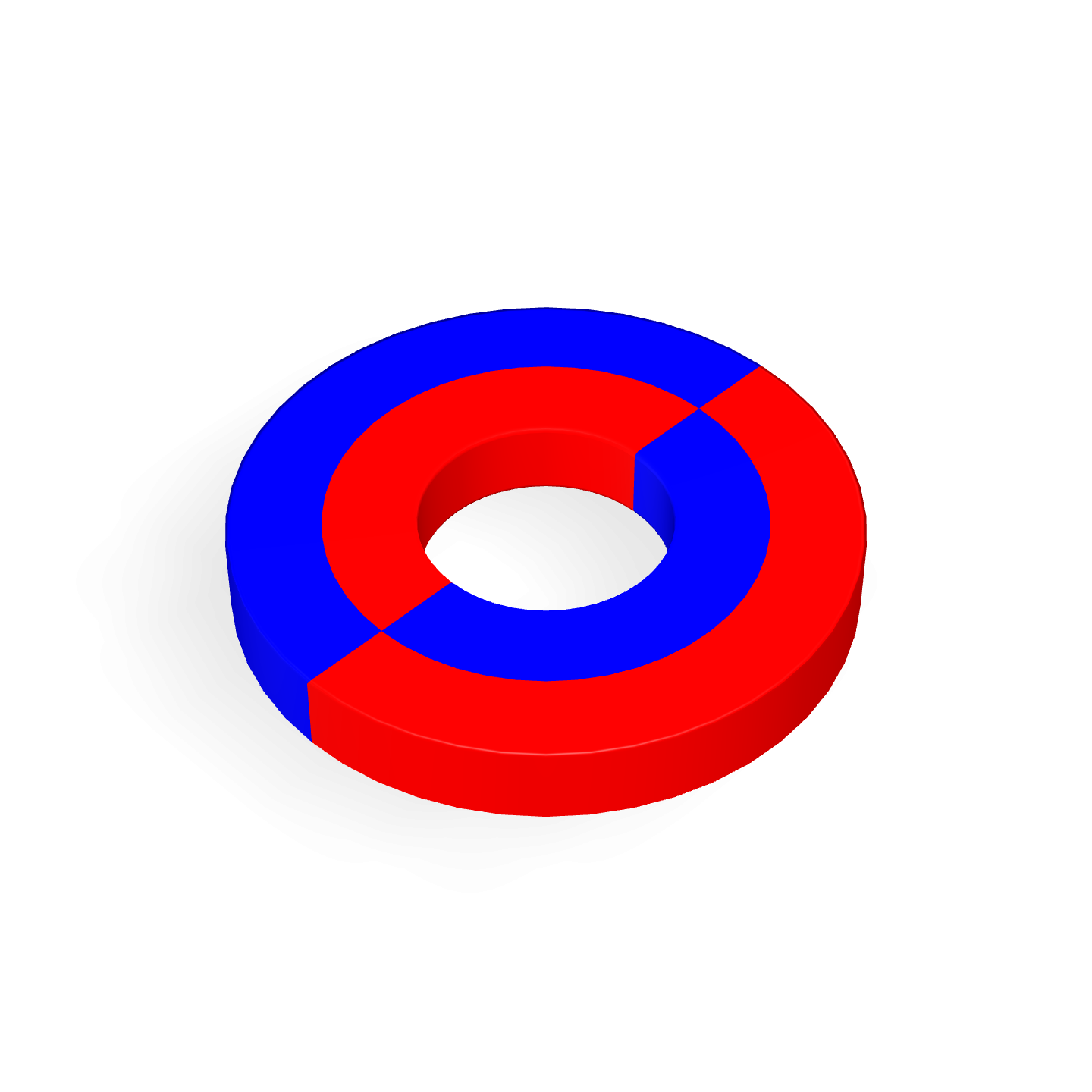

A radial ring magnet is a specialized type of neodymium ring magnet where the magnetic orientation radiates outward from the center or inward towards the center — depending on your application needs. This design creates a continuous, uniform magnetic field around the circumference of the ring, rather than simple north-south poles on opposite faces like conventional ring magnets.

This radial orientation allows for a 360-degree magnetic field, which is crucial in high-speed motor designs, magnetic couplings, and rotary encoders. It’s one of the reasons radial magnets are becoming increasingly sought-after in the automotive, aerospace, and medical device industries.

How Are Radial Ring Magnets Manufactured?

Unlike traditional ring magnets that are sliced from larger blocks, radial magnets are typically made using a isostatic pressing or hot-pressing sintering technique with specialized tooling. These methods allow manufacturers to align the grain structure during the molding process, resulting in optimal magnetization along the radial direction.

Here at Magfine.ca, radial neodymium magnets are manufactured using advanced Japanese quality control processes to ensure maximum magnetic performance and durability — ideal for magnets in Canada that face extreme cold or variable climates.

Key Advantages of Radial Neodymium Ring Magnets

- Uniform 360° Magnetic Field: Enables smoother torque in motors and zero cogging for precision movement.

- Compact, Space-Saving Design: Reduces the overall size of magnetic assemblies while enhancing performance.

- High Energy Product: Neodymium is the strongest commercially available magnet, providing a high magnetic field with a small footprint.

- Thermal Stability: Custom coatings and grades offer improved temperature resistance, ideal for high-performance motors.

Applications of Radial Ring Magnets

These magnets aren't just for lab experiments or hobby kits. Radial neodymium ring magnets are essential components in:

- Brushless DC Motors (BLDC)

- Stepper Motors

- Automotive Servo Motors

- Medical Imaging Devices

- Precision Sensors & Encoders

- Magnetic Couplings

Looking for high-quality magnets to support your project or production line? Browse our growing catalog of industrial magnets online, or contact us for customized solutions.

Why Choose Radial Over Standard Ring Magnets?

With conventional axial or diametric ring magnets, the magnetic field is either vertical or horizontal. This can lead to uneven torque or performance inconsistencies in rotational systems. Radial magnetization, on the other hand, delivers a smoother magnetic flux, ideal for high-efficiency systems.

Additionally, radial neodymium ring magnets simplify the design of motors by eliminating the need for multi-segment arc magnets. Instead, you get a seamless ring that reduces assembly time and improves mechanical balance.

Radial Neodymium Ring Magnets in Canada

As demand for electric vehicles, robotics, and energy-efficient appliances grows across North America, the need for precision magnets in Canada is stronger than ever. That’s where Magfine Corporation North America steps in.

With a heritage of Japanese manufacturing excellence and decades of experience in magnet technology, Magfine is uniquely positioned to supply radial ring magnets tailored for Canadian industries. Whether you need a few samples or a full production run, our team can help deliver precision, power, and consistency.

Customizing Radial Ring Magnets

No two applications are the same. That’s why we offer customization options, including:

- Outer and inner diameter sizing

- Magnetic orientation (inner-radial, outer-radial, or segmented)

- Temperature grades from N35 to N52 and beyond

- Surface coatings (Ni-Cu-Ni, epoxy, Zn, etc.)

If you’re in the design phase and need help specifying your neodymium magnet, our experts can help you choose the best configuration for performance and cost-efficiency.

Where to Buy Radial Neodymium Ring Magnets

Shopping for quality radial magnets shouldn’t be a hassle. At Magfine.ca, we make it easy to find the right industrial magnet for your application. We serve engineers, product developers, universities, and manufacturers all across Canada and beyond.

Whether you need a prototype batch or a full supply chain solution, we offer dependable delivery, expert guidance, and competitive pricing. Explore our radial neodymium magnet collection today.

Frequently Asked Questions

What is the difference between radial and axial ring magnets?

Radial magnets are magnetized outward or inward around the ring’s circumference, while axial magnets have poles on the flat faces. Radial magnets are ideal for rotating equipment, whereas axial magnets are more general-purpose.

Can I order custom radial magnets from Magfine?

Yes! We offer custom sizes, coatings, temperature grades, and magnetization directions tailored to your specific requirements. Reach out here to get started.

Are radial neodymium magnets suitable for Canadian weather?

Absolutely. With corrosion-resistant coatings and high-temperature grades, our magnets are built to withstand Canada’s harsh conditions, from cold winters to humid environments.

Do radial magnets replace arc magnets in motors?

In many cases, yes. Radial ring magnets can provide a more efficient, balanced alternative to segmented arc magnets — especially in high-performance or high-speed applications.

Still have questions? Visit our blog for more insights or contact our team to discuss your next project involving magnets in Canada.

1 comment

Rika Ariyanti

Les aimants en néodyme radiaux sont fascinants en raison de leur puissance et de leurs nombreuses applications. Ils jouent un rôle clé dans la technologie moderne, notamment dans les moteurs et les générateurs. Si vous êtes curieux de savoir comment les coûts des universités publiques et privées se comparent, voici un lien utile : Telkom University Jakarta.