Polyimide Coating Solutions for Magnets: Elevating Performance with Magfine

Since 1986, Magfine has been a trailblazer in magnet coating solutions, consistently innovating to enhance the durability, functionality, and aesthetics of industrial magnet products. In this post, we explore the advantages of polyimide coating—a premium choice for protecting magnets—and examine where it's used across industries, from electronics to aerospace. We'll also spotlight how Magfine's polyimide-coated offerings—and their application to neodymium magnet and industrial magnet product lines—deliver unmatched reliability for clients seeking top-tier performance in magnets in Canada.

1. What Is Polyimide Coating and Why It’s a Game-Changer

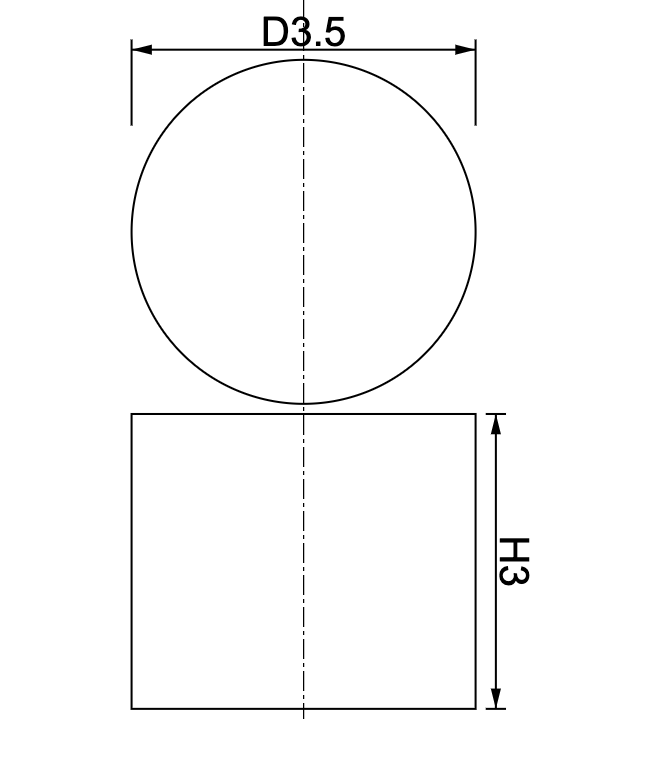

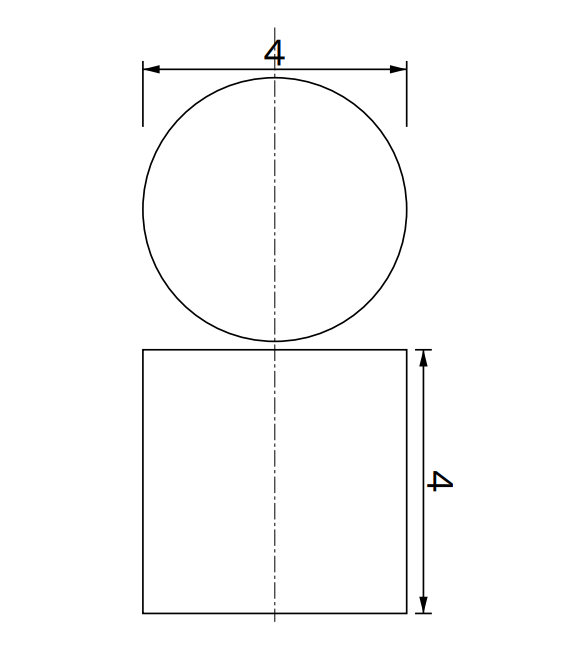

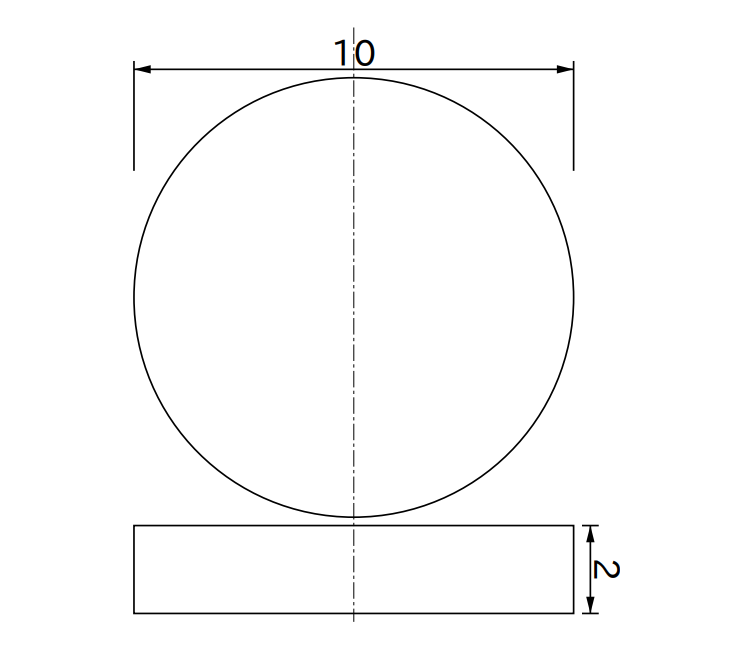

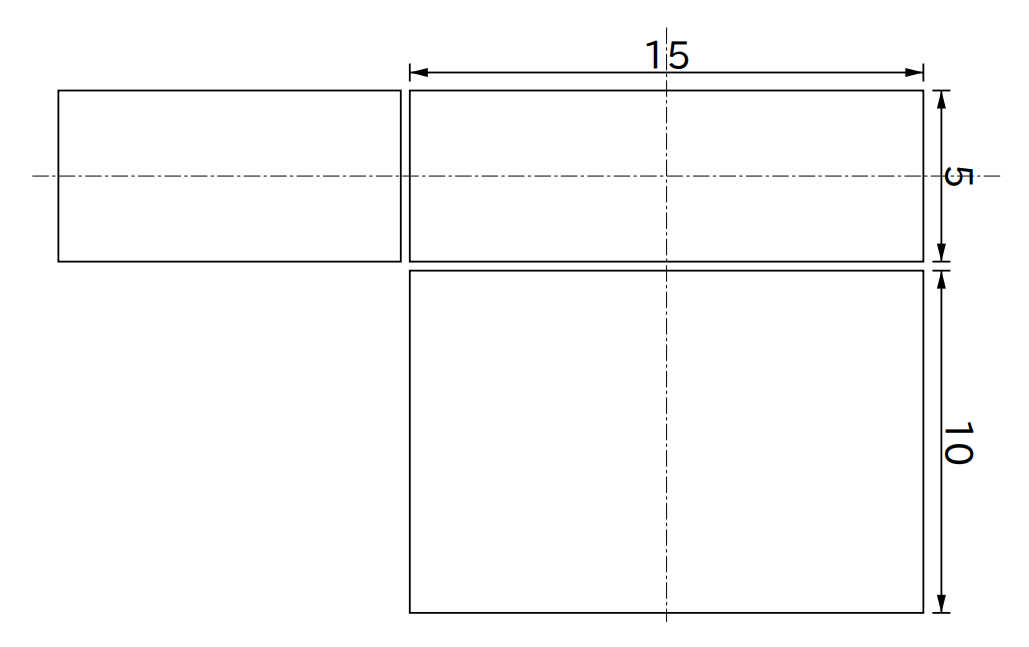

Polyimide is a high-performance polymer known for exceptional heat, chemical, and mechanical resistance. When used as a coating, it dramatically upgrades a magnet’s resilience to extreme conditions. Magfine’s polyimide resin coatings are applied in ultra-thin layers (typically 20–40 µm, though up to 200 µm is possible), delivering airtight protection without bulk—ideal for both neodymium magnets and broader magnet categories.

1.1 Unmatched Thermal Stability

Polyimide coatings can sustain temperatures from as low as –269 °C to well above 300 °C, with continuous service up to approximately 260 °C and momentary exposure up to ~400 °C. In special high-temp magnet applications, such as fusion reactor coils operating near 350 °C, polyimide-insulated coils have demonstrated mechanical properties rivals or surpasses traditional epoxy-bonded magnets.

1.2 Excellent Electrical & Mechanical Performance

Polyimide provides robust electrical insulation—even in demanding environments like 800 V+ electric vehicle systems—by reducing electrical and magnetic losses and offering high dielectric strength and tracking resistance. Its mechanical toughness resists abrasion and outgassing, making it a staple in aerospace-grade insulation.

1.3 Chemical & Environmental Resistance

Polyimide is resistant to chemical exposure, solvents, oils, radiation, and flame, maintaining integrity across variable humidity and temperature—especially when combined with protective layers like PTFE (Polytetrafluoroethylene).

2. Where Polyimide Coating Is Making an Impact

2.1 Electronics & Flexible Circuits

Polyimide is a foundation of modern electronics—from flexible circuits and FPCs (Flexible Printed Circuits) to insulating magnet wires and interconnects. Its flexibility, thin-film capability, and heat resistance make it ideal for high-end electronics.

2.2 Aerospace & Automotive

DuPont’s Kapton films (a brand of polyimide) are widely deployed in aerospace, automotive connectors, and advanced computing gear. Thermoplastic polyimide-coated wires—such as AURUM TPI—are adopted in high-voltage (>800 V) EV power systems for weight savings and reliability.

2.3 Medical & Microelectronics

Tech Etch uses polyimide for precision parts in IOL (Intraocular Lens) haptics and medical devices where biocompatibility, flexibility, and precision are crucial. In microelectronic and MEMS applications, polyimide offers passivation, mechanical buffer, and reliable insulation.

2.4 Anti-Corrosion Coatings

Beyond wire and film, polyimide coatings protect metal substrates—such as infrastructure, pipes, or industrial equipment—from corrosion in harsh environments.

3. Magfine's Edge: Polyimide Coatings for Magnets

Magfine’s advanced polyimide coating applications deliver:

- Ultra-thin, high-density coverage ensuring airtight protection and enhanced mechanical strength, without sacrificing design precision or aesthetics.

- Heat resistance up to 300 °C (or momentarily 400 °C), outperforming epoxy for demanding thermal environments.

- Excellent adhesion (JIS - Japanese Industrial Standards Class 0), impact resistance, minimal moisture absorption, and corrosion prevention—key for industrial magnet and neodymium magnet use cases.

Whether you're sourcing magnets in Canada or globally, Magfine supports your design process with internal links to product pages:

- Contact us for Custom Coating and Magnet Solutions

- Neodymium Magnet Products

- Industrial Magnet Applications

4. Final Thoughts

To wrap up: polyimide coating represents a high-performance, future-forward upgrade for magnets—especially critical for high-temp, high-reliability, or precision-bearing uses. Magfine's decades of expertise ensures your neodymium magnet or industrial magnet receives maximum protection, longevity, and design flexibility. Whether you're sourcing magnets in Canada or beyond, trust Magfine’s polyimide-coated solutions for superior results.