Magnet Plates: Custom Magnetic Solutions for Industrial Applications

In the world of industrial magnetics, the demand for specialized solutions continues to grow. Among the most powerful and versatile of those solutions are magnet plates. Whether you are operating in food processing, recycling, mining, or manufacturing, magnetic plates serve as an essential tool for removing ferrous contaminants from product flows.

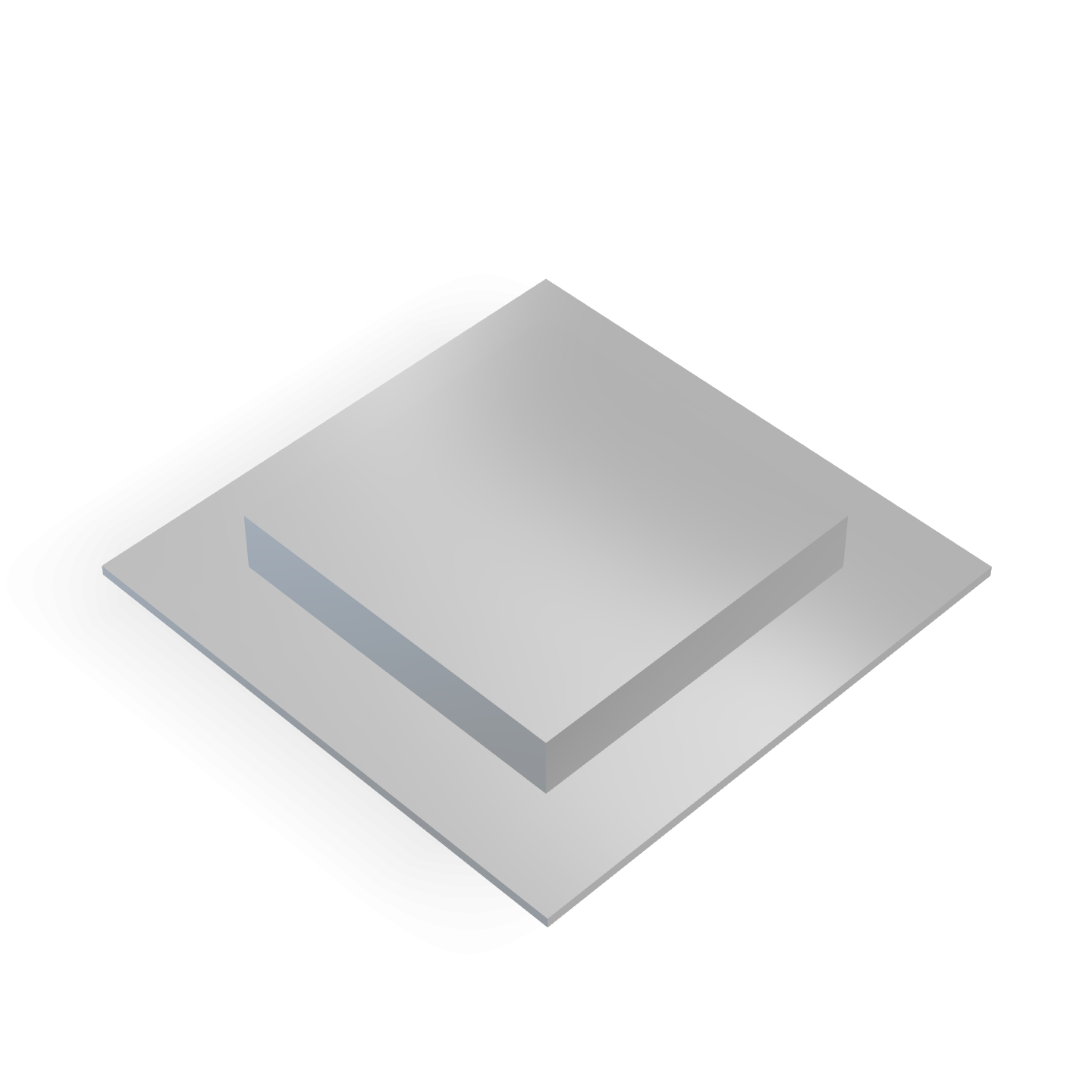

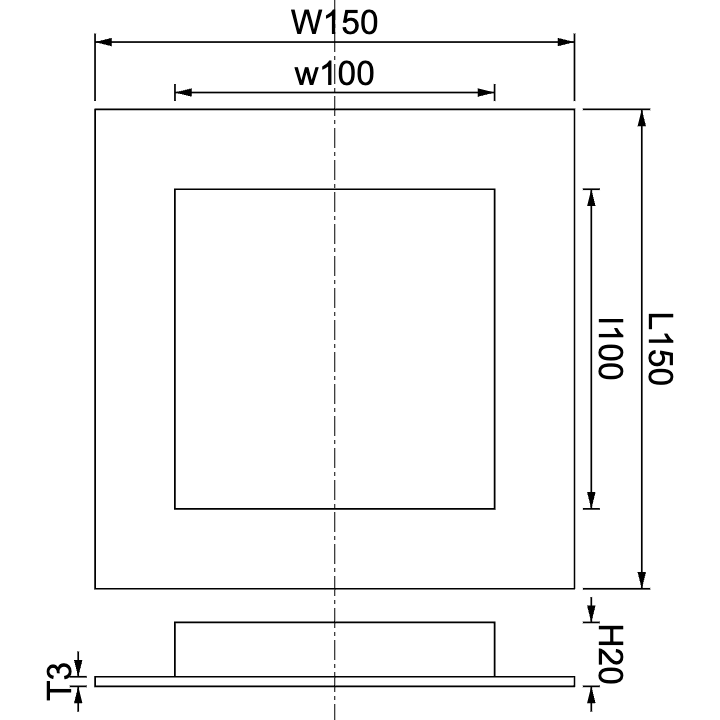

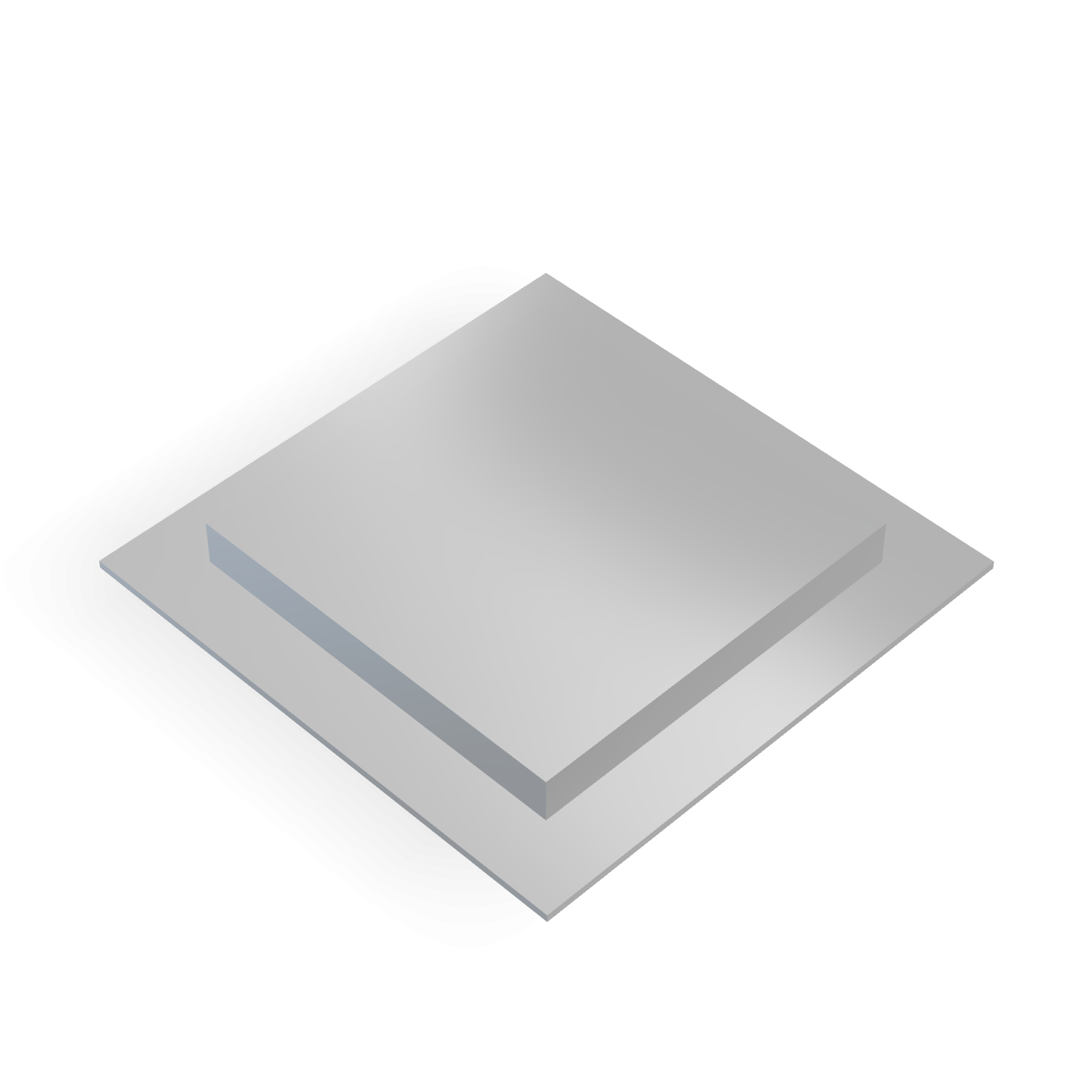

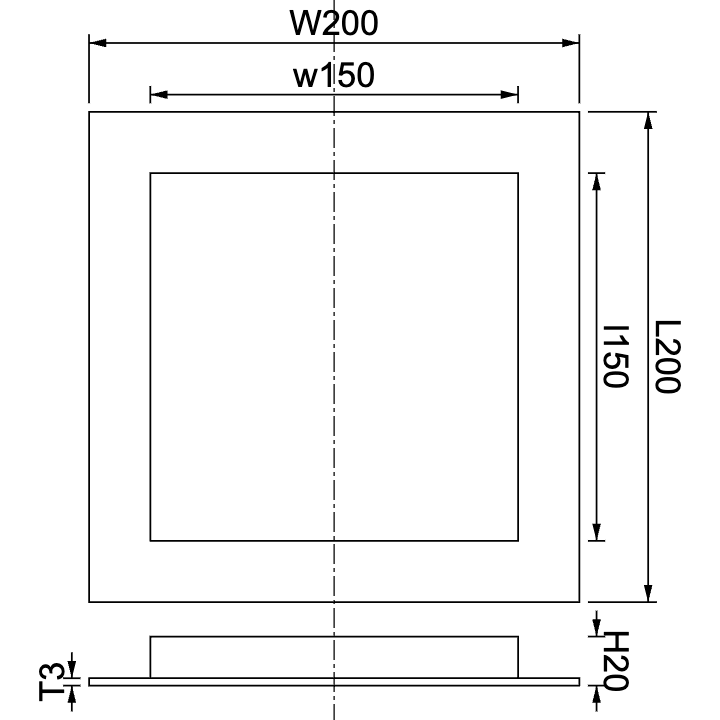

At Magfine Canada, we specialize in providing custom-made magnet plates tailored to your specific operational needs. These are not mass-produced stock items; rather, each magnetic plate is built-to-order based on your equipment setup, product type, and industry requirements.

What Is a Magnet Plate?

A magnet plate is a flat magnetic separator that uses a high-powered magnetic field to draw in and capture ferrous particles from a material stream. They are commonly installed above conveyors or chutes and function without the need for electricity or moving parts, making them both cost-effective and low maintenance.

Often integrated with magnetic bars or tubes in other formats, magnetic plates deliver surface area coverage and easy-clean features essential for contamination control.

Why Are Magnet Plates Custom Made?

Every industrial environment is different. The nature of the material flow, the dimensions of the system, and the intensity of magnetic separation required vary from one facility to another. That’s why we do not stock magnetic plates in our warehouse — each unit is custom fabricated to match your operational parameters.

Our engineers at Magfine work directly with you to determine the most efficient layout, magnet grade, and housing for your application. By tailoring each solution, we ensure you receive maximum separation power and durability.

Applications of Magnet Plates

- Food Processing Facilities

- Recycling Plants

- Wood Processing

- Mining and Aggregate Handling

- Chemical Manufacturing

- Textile and Non-Woven Manufacturing

Magnet plates play a vital role in preventing equipment damage and ensuring product purity. For example, in the food industry, industrial magnets like plates can remove tiny fragments of rust, wire, or steel from flour, grains, or dairy, preventing contamination and costly recalls.

Powerful Magnetic Materials

Magfine’s magnetic plates are crafted using high-strength neodymium magnets or ceramic magnets depending on the application’s temperature and environmental requirements. Neodymium magnet options offer unparalleled strength, ideal for fine ferrous particle extraction.

Whether your facility is dealing with powder, pellet, or granular materials, our magnetic plates can be integrated seamlessly into your existing system.

Benefits of Choosing Custom Magnet Plates

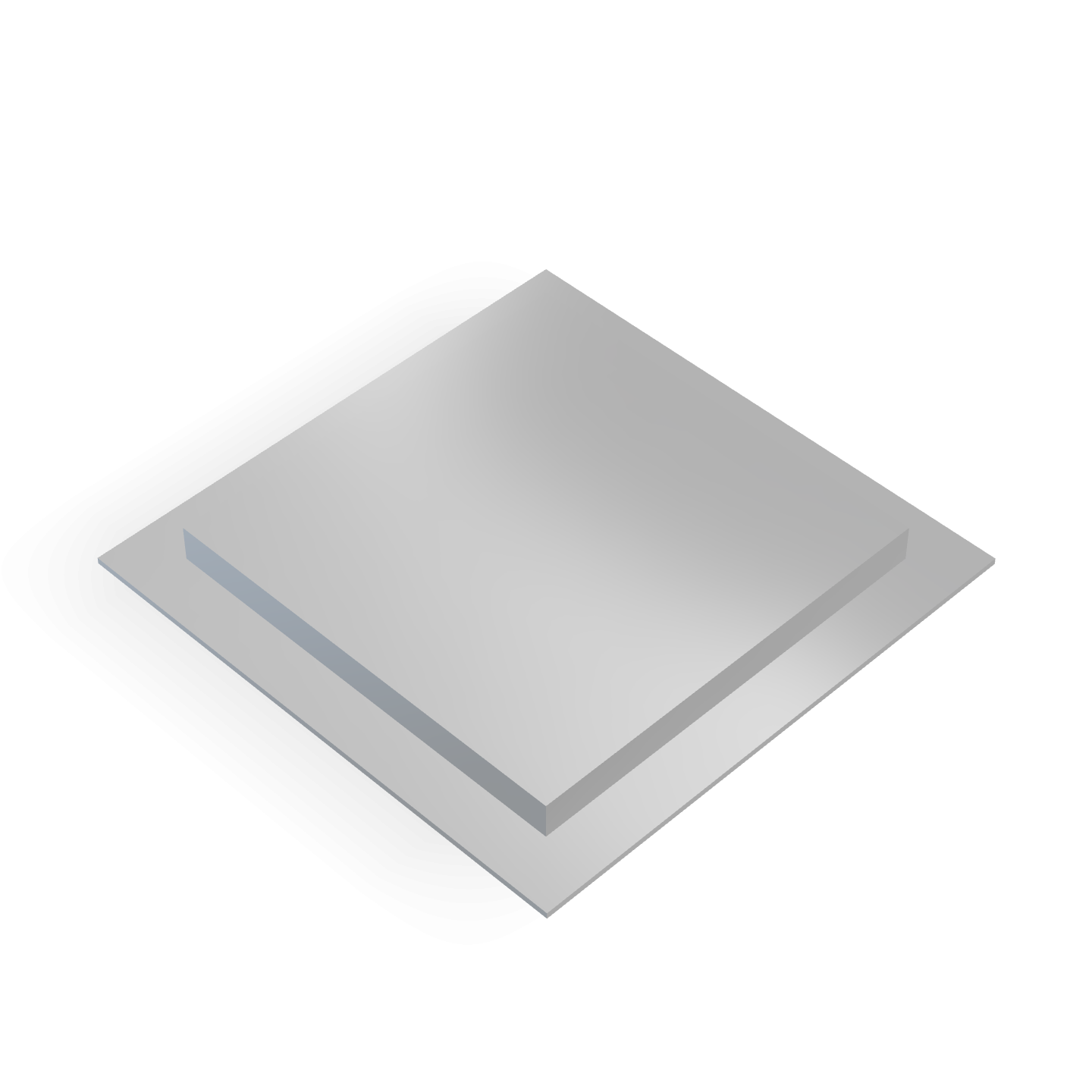

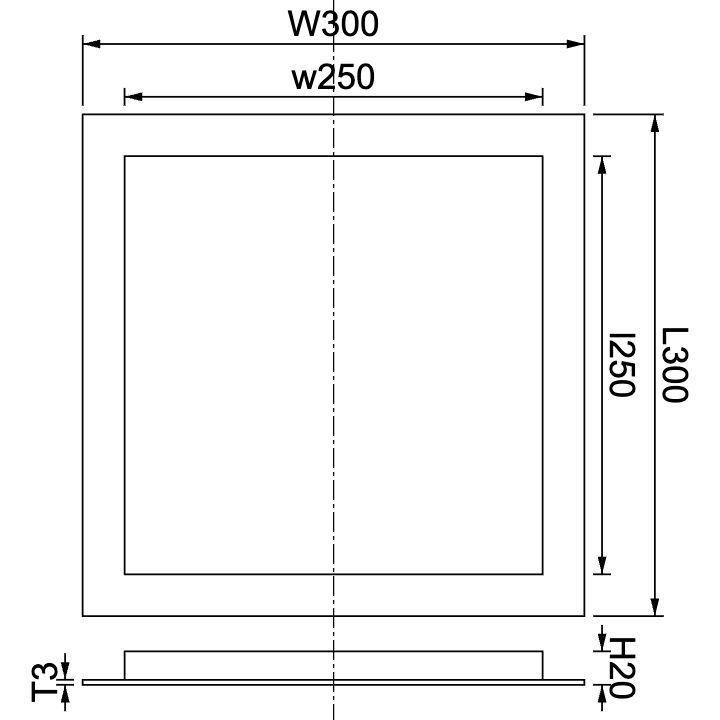

1. Tailored Dimensions

No need to compromise with off-the-shelf sizes. Our custom fabrication ensures precise fitment to your chutes or conveyors.

2. Superior Magnetic Strength

Choose between ceramic or neodymium options. We offer rare-earth magnetic grades to achieve maximum separation even with high throughput volumes.

3. Durability

Our plates are encased in heavy-duty stainless steel to resist corrosion, wear, and harsh chemical exposure. Perfect for industrial-scale production environments.

4. Low Maintenance

With no moving parts or power consumption, magnetic plates require minimal upkeep. We can also design them for easy-clean mechanisms where frequent removal is necessary.

Why Magfine?

As one of the leading suppliers of magnets in Canada, Magfine has built a reputation for precision, reliability, and custom-engineered magnetic solutions. From triangular magnet bars to custom neodymium assemblies, our focus is always on quality and application-specific design.

By working with us, you get:

- Canadian-based consultation and support

- Responsive lead times for custom projects

- Competitive pricing on industrial-grade magnets

- Full project transparency and technical drawings

Ordering Your Custom Magnet Plate

Ordering is simple. Visit our contact page and provide us with your requirements — dimensions, temperature environment, type of material flow, and desired magnetic intensity. We’ll work with you to create a magnetic plate that fits your system and exceeds your expectations.

While we don’t carry magnet plates in inventory due to their custom nature, we ensure fast turnarounds once specifications are approved.

Final Thoughts

If your operation requires the removal of ferrous materials from product flow, magnet plates are one of the most efficient and maintenance-free options on the market. With over a decade of experience providing industrial magnets across Canada, Magfine is your trusted partner for all things magnetic.

Explore our full collection of magnetic products including magnetic bars, and hopper magnets to see how we can support your application.

Frequently Asked Questions About Magnet Plates

What are magnet plates used for?

Magnet plates are used to remove ferrous metal contaminants from materials moving on conveyors or chutes in industrial applications. They are particularly effective in food, recycling, and mining industries.

Can I order a stock size magnet plate from Magfine?

Currently, no. All magnet plates at Magfine are custom-fabricated to meet your exact requirements. This ensures a perfect fit and optimal magnetic performance.

What magnetic materials are used in these plates?

We use both ceramic magnets and high-powered neodymium magnets depending on the needs of your operation. Neodymium magnets provide stronger pull force for finer contaminant removal.

How do I get a quote for a custom magnetic plate?

Visit our contact page and fill out your requirements. Our team will respond with a custom quote and lead time details.

Where is Magfine based?

Magfine Canada operates out of Markham, Ontario, and serves customers across North America looking for premium magnets in Canada.

What is the lead time for custom magnet plates?

Lead times typically vary depending on design complexity and current production volume, but our team strives for rapid delivery without compromising quality.