Cap Neodymium Magnets with Counterbore Holes: Secure Mounting with Industrial Strength

When it comes to mounting solutions that require precision, power, and long-term reliability, Cap Neodymium Magnets with Counterbore Holes are the go-to choice for industries and professionals across Canada. At Magfine.ca, these square, flush-mount industrial magnets are designed for superior holding strength and engineered to meet the demanding needs of manufacturing, assembly, display, and more.

What Are Cap Neodymium Magnets with Counterbore Holes?

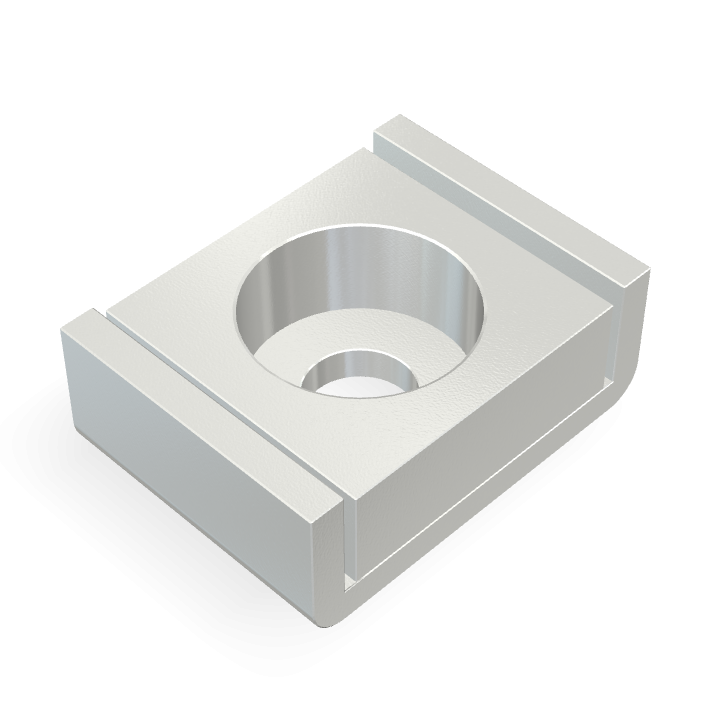

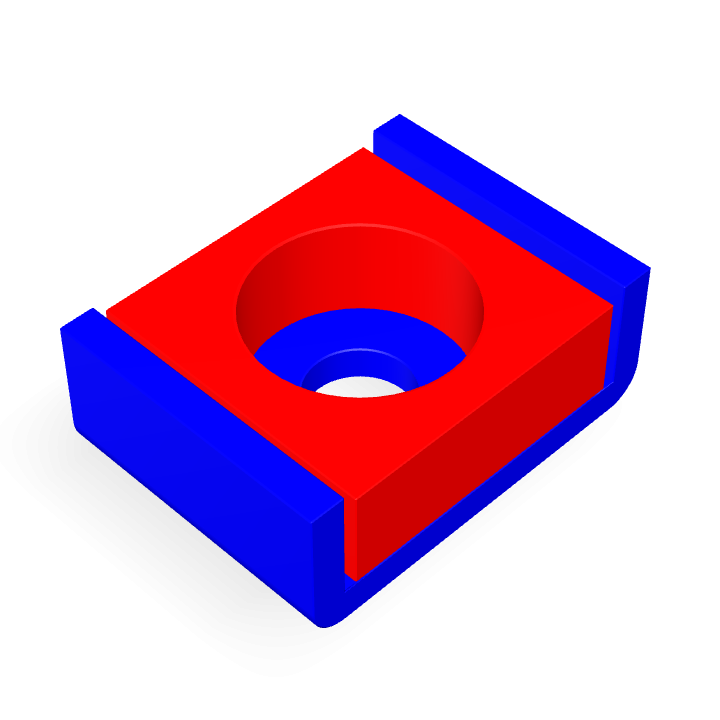

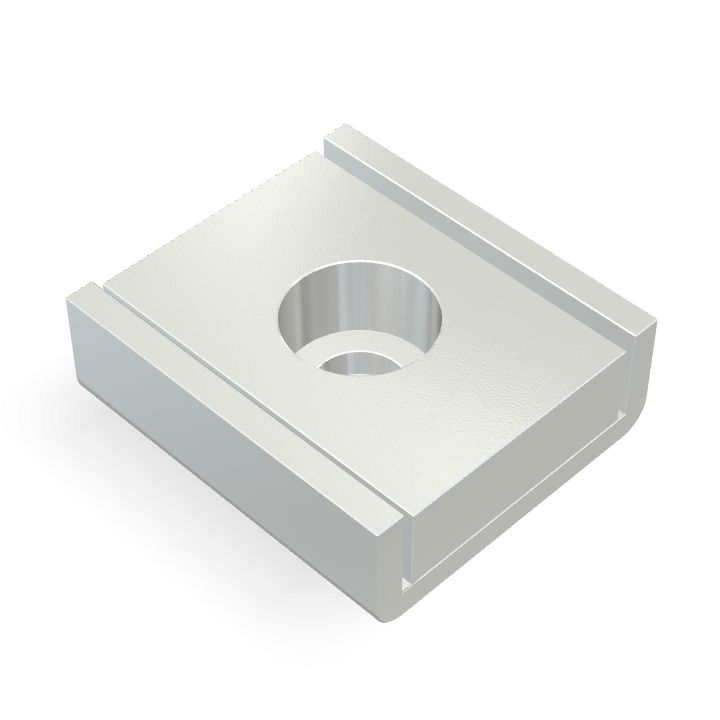

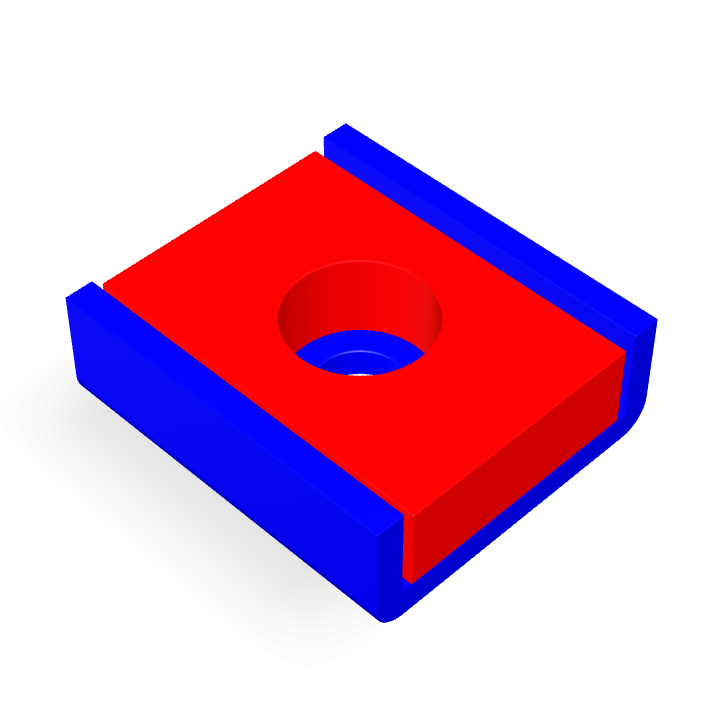

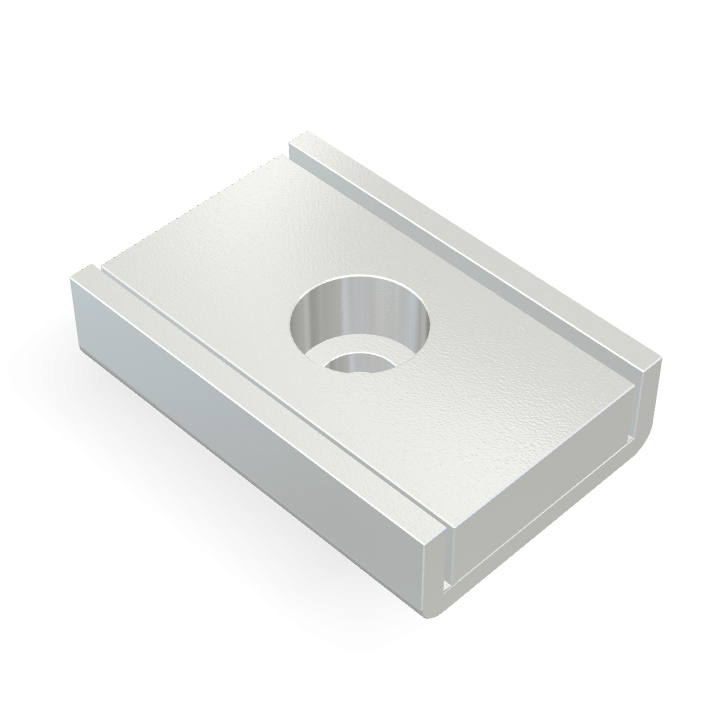

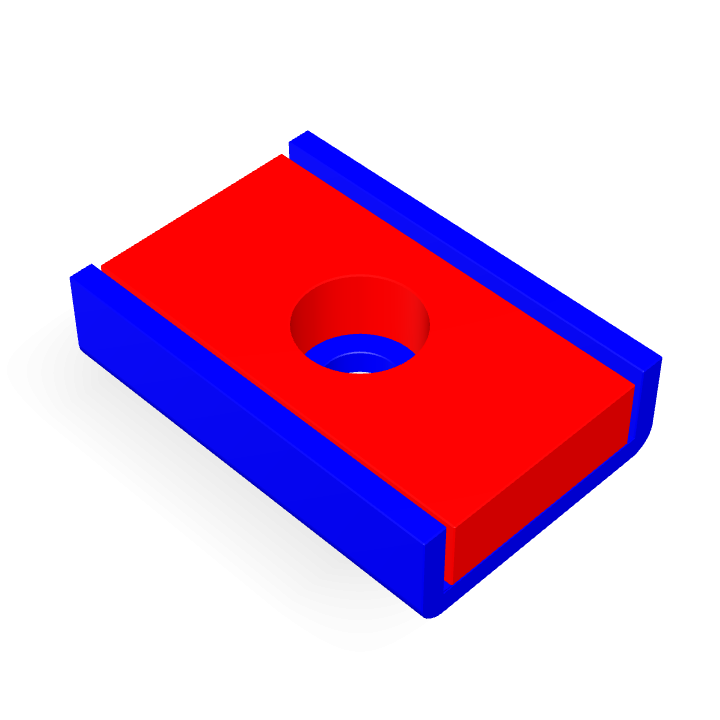

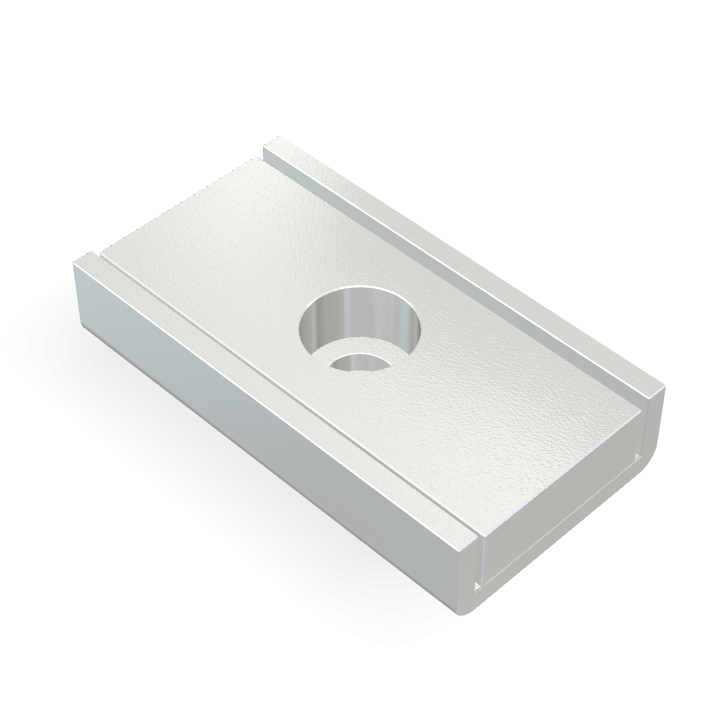

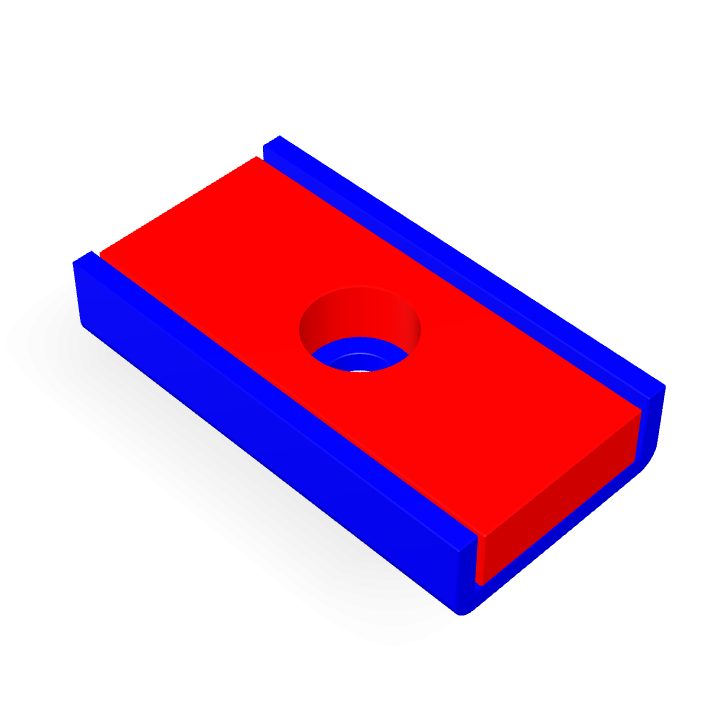

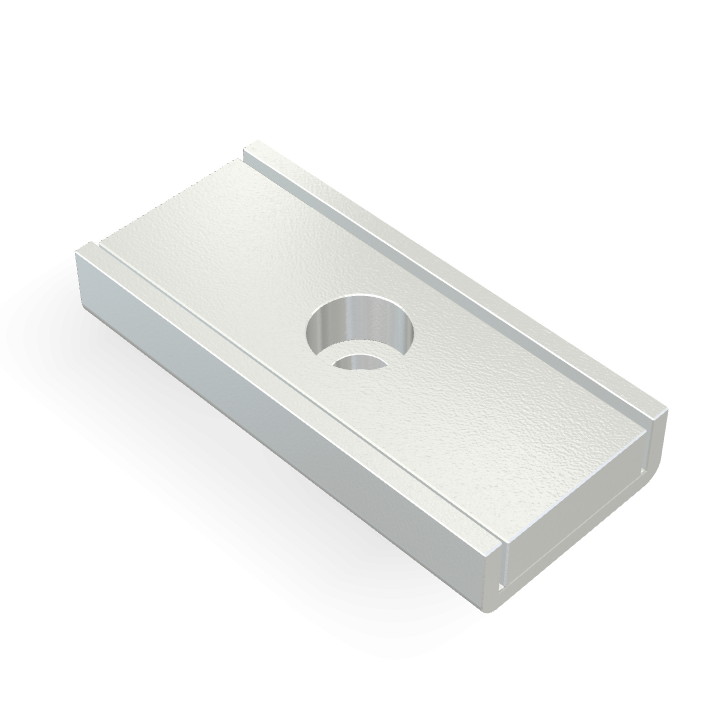

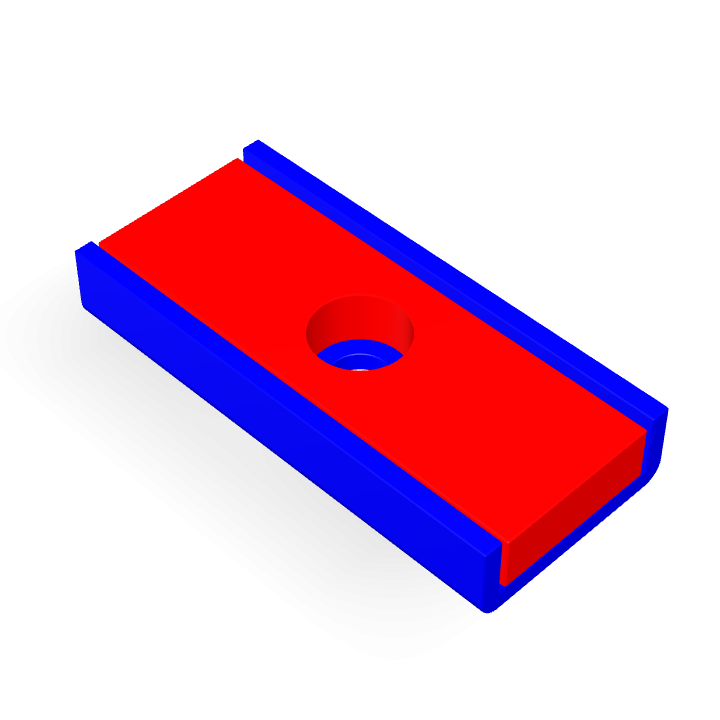

Cap magnets with counterbore holes feature a flat-bottomed mounting hole that allows the head of a machine screw or bolt to sit flush inside the magnet. Unlike countersunk magnets (which are conical), these counterbore versions allow for a clean, even surface contact—ideal for applications where mechanical fastening is critical.

Made from high-grade neodymium magnet material, these block-shaped components deliver extreme magnetic pull force in a compact form factor. Whether used in automated systems or custom builds, their versatility makes them an essential tool in many Canadian industries.

Key Features & Advantages

- Industrial Strength: Available in N35–N52 grades for high pull force and durability.

- Flush Mounting: Counterbore holes support smooth mechanical integration with M3 screws.

- Precision Machining: Clean edges and consistent tolerances for professional results.

- Corrosion Resistance: Finished with nickel or epoxy coatings to endure tough environments.

- Space-Efficient Design: The square block shape fits tightly into structured spaces.

Applications in Canadian Industries

These magnets in Canada are used in a wide array of sectors for both mechanical and magnetic purposes:

- Manufacturing: Mounting jigs, tools, and fixtures on production lines.

- Signage & Displays: Flush-mounted signs in retail and trade shows.

- Automotive: Panel positioning, magnetic mounting brackets, and testing systems.

- Construction & Architecture: Modular fixtures and hidden fastenings for metal surfaces.

- Home & DIY: Cabinet doors, furniture latches, or hidden magnetic attachments.

Explore Our Featured Products

Shop our collection of square cap neodymium magnets with counterbore holes:

Installation Tips for Maximum Hold

- Use compatible M3 flat-head screws that match the counterbore size.

- Mount on clean, dry surfaces to maximize adhesion and stability.

- Ensure flush engagement by not overtightening screws, which may crack the magnet.

Why Choose Magfine.ca for Neodymium Magnets?

- Industry Expertise: With over three decades of innovation and global experience, Magfine is a trusted name in magnet supply.

- Quality Control: All products are manufactured under rigorous standards for strength and consistency.

- Responsive Support: Our Canadian team is here to assist engineers, designers, and procurement teams with any technical questions.

- Fast, Canada-Wide Shipping: We ship directly across Canada with local fulfillment capabilities.

Related Products

Conclusion

If you're looking for a secure, flush-mounted magnetic solution, Cap Neodymium Magnets with Counterbore Holes offer unmatched precision and strength. Trusted across Canadian industries for their high performance and durability, they’re an ideal choice for professional and custom applications alike.

Browse our square counterbore magnet collection today and experience the Magfine difference in quality, performance, and service.

Frequently Asked Questions

What is the difference between a counterbore and countersunk magnet?

A countersunk magnet has a cone-shaped hole that fits flathead screws, while a counterbore magnet has a flat-bottomed recess to house the head of a cylindrical screw or bolt, allowing it to sit flush without the need for a conical fit.

Are counterbore magnets better for heavy-duty applications?

Yes. The counterbore design allows for better torque and load transfer through the mounting screw, making them ideal for industrial uses that require reliability under stress.

Can I use cap magnets outdoors?

Yes, especially if they are coated with protective finishes such as epoxy or triple-layer nickel. However, additional sealing may be necessary in extreme environments.

Do you offer technical guidance for magnet installation?

Absolutely. Our support team can assist with mounting techniques, product selection, and custom solutions tailored to your application.

Can I request bulk pricing?

Yes. Magfine offers bulk purchasing options for OEMs, engineers, and procurement teams. Contact us for volume discounts and lead times.